The Fuel and Engine Bible - how engines work including 2 stroke, 4 stroke and wankel (rotary) engines, fuel, octane rating, power, bhp, gas types and grades, carburettors, fuel injection, tuning, tweaking, nitrous, turbos, superchargers, chipping, hybrids, how to keep your engine running at peak fitness and much more.

The Fuel & Engine Bible

Suck, squeeze, bang, blow

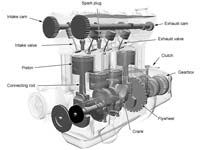

Not a sexual maneuver, but rather the common description for how an internal combustion engine works. The basic way all internal combustion engines work is to take a mixture of fuel and air, compress it, ignite it either with a spark plug or by self-igntion (in the case of a diesel engine), allow the explosion of combusting gasses to force the piston back down and then expel the exhaust gas. The vertical movement of the piston is converted into rotary motion in the crank via connecting rods. The crank then goes out to the gearbox via a flywheel and clutch, and the gearbox sends the rotary motion to the wheels, driving the vehicle forwards.

The diagram to the left is for reference for the technical jargon that will pop out on the rest of this page. It shows an inline-4 engine with dual overhead cams.

Nikolaus Otto

If you want to be pedantic, the suck-squeeze-bang-blow cycle of a 4 stroke engine should be called the Otto Cycle, after its inventor Nikolaus Otto. The development of the internal combustion engine is quite interesting, and rather than add even more clutter to this page, enquiring minds can read about the history of the internal combustion engine here. The rest of us will carry on....

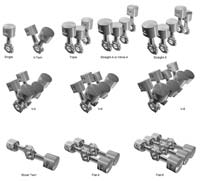

Engine layouts

Here are some illustrations of the most common types of cylinder layout you'll find in engines today. Singles are typically used in motorbikes, snowblowers, chainsaws etc. V-twins are also found in motorbikes. The triple is almost unique to Triumph motorbikes where they call it the Speed Triple, or the 675. Inline-fours are the mainstay of car engines, as well as being found in some motorbikes too such as the BMW K1200S. Inline fives used to be used a lot in Audis but have found a new home in current Volvos. The V5 is something you'll find in some VWs. The V6 has the benefits of being smoother than an inline-four but without the fuel economy issues of a V8. Boxer engines are found in BMW motorbikes (twins) and Porsches and Subarus (fours and sixes). You had no idea, did you?

The difference between 4 stroke and 2 stroke engines

First, some basic concepts. Well one basic concept really - the most common types of internal combustion engine and how they work. It's worth reading this bit first otherwise the whole section on octane later in the page will seem a bit odd. Almost every car sold today has a 4 stroke engine. So do a lot of motorbikes, lawnmowers, snowblowers and other mechanical equipment. But there are still a lot of 2 stroke engines about in smaller motorbikes, smaller lawnmowers, leaf-blowers, snowblowers and such.

The difference between the two engine types is the number of times the piston moves up and down in the cylinder for a single combustion cycle. A combustion cycle is the entire process of sucking fuel and air into the piston, igniting it and expelling the exhaust.

How 2 stroke engines work

A 2 stroke engine is different from a 4 stroke engine in two basic ways. First, the combustion cycle is completed within a single piston stroke as oppose to two piston strokes, and second, the lubricating oil for the engine is mixed in with the petrol or fuel. In some cases, such as lawnmowers, you are expected to pre-mix the oil and petrol yourself in a container, then pour it into the fuel tank. In other cases, such as small motorbikes, the bike has a secondary oil tank that you fill with 2 stroke oil and then the engine has a small pump which mixes the oil and petrol together for you.

The simplicity of a 2 stroke engine lies in the reed valve and the design of the piston itself. The picture on the right shows a 4 stroke piston (left) and a 2 stroke piston (right). The 2 stroke piston is generally taller than the 4 stroke version, and it has two slots cut into one side of it. These slots, combined with the reed valve, are what make a 2 stroke engine work the way it does. The following animation shows a 2 stroke combustion cycle. As the piston (red) reaches the top of its stroke, the spark plug ignites the fuel-air-oil mixture. The piston begins to retreat. As it does, the slots cut into the piston on the right begin to align with the bypass port in the cylinder wall (the green oblong on the right). The receding piston pressurises the crank case which forces the reed or flapper valve (purple in this animation) to close, and at the same time forces the fuel-air-oil mixture already in the crankcase out through the piston slots and into the bypass port. This effectively routes the mixture up the side of the cylinder and squirts it into the combustion chamber above the piston, forcing the exhaust gas to expel through the green exhaust port on the left. Once the piston begins to advance again, it generates a vacuum in the crank case. The reed or flapper valve is sucked open and a fresh charge of fuel-air-oil mix is sucked into the crank case. When the piston reaches the top of its travel, the spark plug ignites the mixture and the cycle begins again.

For the same cylinder capacity, 2 stroke engines are typically more powerful than 4 stroke versions. The downside is the pollutants in the exhaust; because oil is mixed with the petrol, every 2 stroke engine expels burned oil with the exhaust. 2 stroke oils are typically designed to burn cleaner than their 4 stroke counterparts, but nevertheless, the 2 stroke engine can be a smoky beast. If, like me, you grew up somewhere in Europe where scooters were all the rage for teenagers, then the mere smell of 2 stroke exhaust can bring back fond memories. The other disadvantage of 2 stroke engines is that they are noisy compared to 4 stroke engines. Typically the noise is described as "buzzy".

How 4 stroke engines work

4 stroke engines are typically much larger capacity than 2 stroke ones, and have a lot more complexity to them. Rather than relying on the simple mechanical concept of reed valves, 4 stroke engines typically have valves at the top of the combustion chamber. The simplest type has one intake and one exhaust valve. More complex engines have two of one and one of the other, or two of each. So when you see "16v" on the badge on the back of a car, it means it's a 4-cylinder engine with 4 valves per cylinder - two intake and two exhaust - thus 16 valves, or "16v". The valves are opened and closed by a rotating camshaft at the top of the engine. The camshaft is driven by either gears directly from the crank, or more commonly by a timing belt.

The following animation shows a 4 stroke combustion cycle. As the piston (red) retreats on the first stroke, the intake valve (left green valve) is opened and the fuel-air mixture is sucked into the combustion chamber. The valve closes as the piston bottoms out. As the piston begins to advance, it compresses the fuel-air mix. As it reaches the top of its stroke, the spark plug ignites the fuel-air mix and it burns. The expanding gasses force the piston back down on its second stroke. At the bottom of this stroke, the exhaust valve (right green valve) opens, and as the piston advances for a second time, it forces the spent gasses out of the exhaust port. As the piston begins to retreat again, the cycle starts over, sucking a fresh charge of fuel-air mix into the combustion chamber.

Because of the nature of 4 stroke engines, you won't often find a single-cylinder 4 stroke engine. They do exist in some off-road motorbikes but they have such a thump-thump-thump motion to them that they require some large balancing shafts or counterweights on the crank to try to make the ride smoother. They also take a little longer to start from cold because you need to crank the single piston at least twice before a combustion cycle can start. Any more than one piston and the engine gets a lot smoother, starts better, and is nowhere near as thumpy. That's one of the advantages of V-6 and V-8 engines. Apart from the increased capacity, more cylinders typically means a smoother engine because it will be more in balance.

Geek trivia: Mercedes-Benz needed to increase the performance of their diesel passenger cars back in the 70's as their market share in the US was increasing. As professionals with big V-8 luxury cars were trading them in for 2.4l diesels, the demand for performance had to be addressed. Mercedes did not want to retool their 114/115 series chassis and there wasn't enough room in the engine bay for a six cylinder diesel. There was, however, room for a straight-5. Benz engineers just hung another cylinder on the back of the 4 cyl block and presto! The five cylinder engine was born. This engine acquired a lot of status among the high line car owners. When Audi introduced the C2 series cars (the 5000 in America, the 100 in Europe) in 1976, they offered a 5-cylinder petrol engine too. It was basically a 1.8 litre 4-cylinder engine with an extra cylinder. That took it up to 2.0 litres but the fifth piston made such an enormous difference to the smoothness of the engine that it was often mistaken for a V6 or V8. Why only 5 cylinders instead of going for a V6? Partly for the same rationale as Mercedes (and it was a really tight fit) but primarily because Benz had made the straight-5 configuration fashionable. A straight-5 was also more fuel-efficient than a V6. It's also worth pointing out that nowadays, both Audi and VW have V5 engines with three cylinders in one bank and two in the other. Same smoothness, better gas-mileage.

Like the site? The page you're reading is free, but if you like what you see and feel you've learned something, a small donation to help pay down my car loan would be appreciated. Thank you.

4 stroke Diesel Engines

Mechanically, 4 stroke diesel engines work identically to four-stroke petrol engines in terms of piston movement and crank rotation. (To be historically accurate, petrol engines are mechanically similar to diesel engines - diesel engines came first) It's in the combustion cycle where the differences come through. First, during the intake cycle, the engine only sucks air into the combustion chamber through the intake valve - not a fuel/air mix. Second, there is no spark plug. Diesel engines work on self-ignition, or detonation - the one thing you don't want in a petrol engine (see the section on Octane later). At the top of the compression stroke, the air is highly compressed (over 500psi), and very hot (around 700 °C - 1292°F). The fuel is injected directly into that environment and because of the heat and pressure, it spontaneously combusts (this system is known as direct-injection). This gives the characteristic knocking sound that diesel engines make, and is also why pre-igniting petrol engines are sometimes refered to as 'dieseling'.

Petrol engines typically run compression rations around 10:1, with lower end engines down as low as 8:1 and sportier engines up near 12:1. Diesel engines on the other hand typically run around 14:1 compression ratio and can go up as high as 25:1. Combined with the higher energy content of diesel fuel (around 147,000 BTU per gallon versus 125,000 BTU for a gallon of petrol), this means that the typical diesel engine is also a lot more efficient than your common or garden petrol engine, hence the much higher gas-mileage ratings.

Because of the design of the diesel engine, the injector is the most critical part and has been subjected to literally hundreds of variations in both design and position. It has to be able to withstand massive pressures and temperatures, yet still deliver the fuel in a fine mist. One other component that some diesel engines have is a glowplug. From cold, some lower-tech engines can't retard the ignition enough, or get the air temperature high enough on startup for the spontaneous combustion to happen. In those engines, the glowplug is literally a hot wire in the top of the cylinder designed to increase the temperature of the compressed air to the point where the fuel will combust. These engines typically have a pictograph on the dashboard that looks like a lightbulb. When starting the engine cold, you need to wait for that light to go out - basically you're waiting for the glowplugs to get up to temperature. In really old diesel designs, this could be as long as 10 seconds. Nowadays it's nearly instantaneous, or in the case of advanced ECM systems, not needed at all.

2 stroke Diesel Engines

Would you believe there is such a thing as a 2 stroke diesel engine? The two-stroke cycle described above turns out to be highly beneficial for the diesel model, the major difference being the inclusion of exhaust valves at the top of the cylinder. The burn cycle works similarly too. At the top of the piston travel, the air is hot and compressed, just like in a 4 stroke diesel. And like the 4 stroke, the injector sprays fuel in at that point and it self-combusts. As the gasses expand, the piston is forced downwards and towards the bottom of its stroke, the exhaust valves on the top of the cylinder open. Because the gas is still expanding at this point, the combustion chamber empties itself through the open valves. At the very bottom of the power stroke, the piston uncovers the air intake and pressurised air fills the combustion chamber forcing the last remnants of the exhaust gas out. As the piston begins its compression stroke, the exhaust valves close and the air is compressed and voila - a two-stroke diesel engine. The other difference between a 4 stroke and 2 stroke diesel engine is that the 2 stroke variety must have a turbocharger or supercharger; you'll notice I mentioned the air intake fills the cylinder with pressurised air. That doesn't happen by magic.

As with 2 stroke petrol engines, every downward piston stroke is a power stroke, meaning the 2 stroke engine has the potential to product twice as much power as its 4 stroke sibling. Typically you'll find 2 stroke diesels in maritime engines (like those on freighters, tankers and cruise ships) and diesel-electric trains where more power is needed for the same size of engine.

"Clean" diesels? Toyota's D-Cat and DPNR

Old-school diesel engines used to sound like tractors when you started them on a cold morning, and they used to spew particulates out of the exhaust to the point where the back of the car went black. Newer generation diesels start much less noisily but for the most part still have some issues with particulates in the exhaust. Toyota claim to have solved this with their D-Cat and DPNR system. D-Cat stands for Diesel Clean Advanced Technology and DPNR stands for Diesel Particulate NOx Reduction. The operating principle is fairly sound. D-Cat is an advanced computer-controlled system for cleaning diesel exhaust gasses which relies on the DPNR catalyser. This is a combination of particle filters and normal gas-reduction catalysing metals that remove particulates, sulphur dioxide (SO2) and nitrogen dioxide (NO2) from the exhaust gasses. A sensor measures can tell when these filters are nearly full at which point a fifth diesel-injector sprays a little fuel directly into the exhaust system. Combined with the exhaust gas recirculation system, this results in all the collected pollutants being burned off, cleaning the filter in the process. DPNR requires ultra-low sulfur diesel (ULSD) to work properly.

Shortly after this system was launched on the D-4D engined 2.0litre Toyota Avensis, the complaints started to come in. Notably, Dutch car magazine AutoWeek (issue 42 / 2006) exposed the problem when their DPNR-equipped Avensis started driving around with a huge cloud of white smoke pouring out of the exhaust. They weren't the only ones to have this problem. Hundreds of complaints were filed in Germany and other European countries for the same thing. The problem was that the D-Cat/DPNR system needs to 'regenerate' as described above. The particulate and gas filters are cleaned via a combustion mechanism in the exhaust, but this only happens at speeds below 160km/h (99mph), and takes about 20 minutes each time. In Germany especially, where they still have sections of unlimited-speed autobahns, people had been driving well over that speed for miles on end, then stopping and turning the car off, only to repeat the cycle twice a day during their commute. When this happens, the DPNR system never gets time to regenerate normally and the particle filters become clogged and the DPNR system forces a clean cycle to happen. This forced combustion results in white smoke as there are too many pollutants trying to be burned off at the same time. And not just a little white smoke. In the AutoWeek test, they thought their Avensis was on fire it was trailing so much smoke. Toyota promised to sort this problem out with an improved version of D-Cat fitted to the higher-spec 2.2litre engine.

As of 2011 there wasn't much talk about this any more although there is still reference to the problem in a Toyota TSB (White Smoke From Exhaust, DNPR Only)

Interference vs. non-interference engines

It's worth mentioning the two sub-types of 4 stroke engine at this point. Because the valves always open inwards, into the combustion chamber, they take up some space at the top of the chamber. In an interference engine, the position of the piston at the top of its stroke will occupy the same physical space that the open valves do whilst the piston is at the bottom of its stroke. It's important to know if your engine is an interference engine because if the timing belt breaks, at least one set of valves will stop in the open position and the momentum of the engine will ram the piston in that cylinder up into the valves requiring a very expensive engine repair or replacement. In a non-interference engine, the valves do not occupy any space that the piston could move into, so if your timing belt snaps on one of these engines, in 99% of cases you won't suffer any valve damage because the piston cannot physically touch the open valves. That is the technical explanation of why its important to get your timing belt changed at the manufacturer-specified mileage.

The picture here shows the difference between the two types. On the left, circled in red is where the open valve interferes with the position of the piston at the top of its travel. On the right, a non-interference engine shows there is still a gap at the same point (exaggerated for my picture).

Top Dead Centre (TDC) and ignition timing

When a piston in an engine reaches the top of its travel, that point is known as Top Dead Centre or TDC. This is important to know because I don't think any engine actually fires the spark plug with the pistons at TDC. More often than not, they fire slightly before TDC. So how does your ignition system work, and what is ignition timing all about?

Well generating the spark is the easy part. The electrical system in your car supplies voltage to your coil and ignition unit. The engine will have a trigger for each cylinder, be it a mechanical trigger (points), electronic module or crank trigger. Whatever it is, at that point, the engine effectively sends a signal to the coil to discharge into the high voltage system. That charge travels into the distributor cap and is routed to the relevant spark plug where it is turned into a spark. The key to this, though, is the timing of the spark in relation to the position of the piston in the cylinder. Hence ignition timing. Having the spark ignite the fuel-air mixture too soon is basically the same as detonation and is bad for all the mechanical components of your engine. Having the spark come along too late will cause it to try to ignite the fuel-air mixture after the piston has already started to recede down the cylinder, which is inefficient and loses power.

Timing the spark nowadays is usually done with the engine management system. It measures airflow, ambient temperature, takes input from knock sensors and literally dozens of sensors all over the engine. It then has an ignition timing map built into its memory and it cross references the input from all the sensors to determine the precise time that it should fire the spark plug, based on the ignition timing map. At 3000rpm, in a 4 cylinder engine, it does this about 100 times a second. In older systems, the spark timing was done using simple mechanical systems which had nowhere near the ability to compensate for the all the variables involved in a running combustion engine.

Typically as an engine revs quicker, the ignition timing needs to advance because the spark needs to get to the cylinder more quickly. Why? Well the fuel-air mix takes a finite amount of time to combust. It won't burn any quicker or slower for any given engine speed. So for higher speeds, the mixture needs to be ignited earlier in the cycle to ensure that it begins to burn at the optimum timing point. In modern systems, this is all taken account of in the ignition timing map. On older mechanical system, they used mechanical or vacuum advance systems, so that the difference in the amount of vacuum generated in the intake manifold, determined the advance/retard amount of the timing.

Checking ignition timing

Despite the speed that an engine turns, it is possible for mere mortals like you and me to be able to check the ignition timing or an engine using (and you'd have never guessed this) an ignition timing light. Timing lights are typically strobe lights. They work by being connected to the battery directly and then having an induction coil clamped around one of the spark plug leads - normally the first or last cylinder in the engine depending on the manufacturer. When the engine fires the spark plug for that cylinder, the inductive loop detects the current in the wire and flashes the strobe in the timing light once. So if the engine is ticking over at 1100rpm, the strobe will flash 550 times a minute (4 stroke engine, remember?). Fantastic. So you're now holding a portable rave lighting rig but how does this help you see the timing of an engine? Well it's simple. You must have seen strobe lights working somewhere - a rave, a stage show - they're used to effectively freeze the position of something in time and space by illuminating it only at a certain point and for a fraction of a second. Shooting a strobe at someone walking in a dark room will result in you seeing them walk as if they were a flip-book animation on a reel of film. This effect is what's used to visualise the timing of your engine. Somewhere on the front of the engine there will be a notch near one of the timing belt pulleys and stamped into the metal next to it will be timing marks in degrees. On the pulley itself there will be a bump, recess or white-painted blob. When you point the timing light down towards the timing belt pulley, remember it fires once for each firing of the cylinders? Each time it fires, the white blob on the pulley should be at the same position in its rotation - the strobe fires once for each ignition spark at which point the mark should be in the same place, and the effect to you is that the whole pulley, timing mark and all, are now standing still in the strobe light. The mark on the pulley will line up with one of the degree marks stamped on the engine, so for example if the white dot always aligns with the 10° mark, it means your engine is firing at 10 degrees before TDC. When you rev the engine, the timing will change so the mark will move closer or further away from the TDC mark depending on how fast the engine is spinning.

Note that in some engines, the two marks are simply painted or stamped, and there are no degree markings. In this case, the marks align when the first piston is exactly at TDC.

Check the timing marks first

After all that, it's worth pointing out that crank timing marks can be way off so it's worth confirming that your TDC marker is actually TDC before pratting about with the timing. It's not as bad now as it used to be, but in the bad old days, Rover V8's were particularly bad for this, with some being as much as 12° off! So how you do confirm your TDC really is TDC? Small cameras, a good set of feeler gauges, some cash and someone who knows what they're doing.

Timing marks on cam belt pulleys

The same timing marks exist stamped into the metal near, and on the pulley on the end the cam. Essentially these marks are used to line up the cam to the correct position when you're changing the timing belt. You have to make sure the engine is rotated to TDC and that the cams are properly aligned too. If you don't, the cams will spin permanently out-of-synch with the engine crank and the engine will run badly, if at all.