The Fuel and Engine Bible - how engines work including 2 stroke, 4 stroke and wankel (rotary) engines, fuel, octane rating, power, bhp, gas types and grades, carburettors, fuel injection, tuning, tweaking, nitrous, turbos, superchargers, chipping, hybrids, how to keep your engine running at peak fitness and much more.

The Fuel & Engine Bible

"Tuning" your engine - how to get more power

Not satisfied with the power your lump is giving you? There are solutions, and of course they depend almost entirely on how deep your pockets are. Almost any engine in any car can be adjusted, tweaked, modified and tuned to give more power. The more money you have to spend, the quicker your car will go.

Customizing your engine helps push your vehicle beyond its limits. You need only reliable, premium quality performance parts to build a custom engine. If youre looking for a trustworthy place to start shopping online, CARiD is that place. Dont wait another moment and choose from the great variety of performance engine parts for cars & trucks at CARiD.com. Besides quality and reliable service, the parts are offered at fairly competitive prices.

Chipping / remapping

About the simplest and easiest modification to most modern engines is called chipping. When it was first introducted, it involved removing the chip that contains the ignition map from the engine management system, and replacing it with one with a modified map. The new chip was designed for better torque, increased power, or just smoothing out flat spots in the power or torque curve of the engine. Nowadays, chipping should be more accurately referred to as Remapping. Gone are the days when you could just a whip a chip out of the ECU. That's so 90's. Today, when you cough up your hard earned cash at a tuner house, they'll plug a laptop in to your engine diagnostics port and upload new software which changes all manner of things from turbo control, fuelling maps, engine load and torque limiters all the way up to throttle-by-wire response (where applicable). They write their own software after studying (read: reverse-engineering) the car's ECU parameters using a rolling road and a laptop hooked to the diagnostics port. From there they can re-write the engine management software to do what they want rather than what the manufacturer wanted. Petrol cars respond well to remapping, but for some reason, diesels respond much better, especially VW diesels. It's not uncommon for a remapped VW ECU to generate 30% more power and torque after it's been breathed on. Add a turbo to that and you can see even wilder gains. Realistically though you ought to expect around a 5-7% increase in horsepower from a chip or remapping operation.

Picture credit: Superchips

Getting your car remapped will take a couple of hours if you go to a reputable tuner house. They'll pop your steed on a rolling road and hook it up to a dyno to get it right. In some cases, you can get a remapping module which sits in-line with the factory-fitted ECU, and then you can download or create your own mappings and upload them to the unit yourself. Power Commander are one of the more notable manufacturers of this sort of system, although theirs is predominantly designed for motorbikes.

But how can this work? More torque and horsepower without changing anything in the engine? Well bear in mind that from the factory, most cars are sold to be more economy and comfort biased than performance biased. Most engines have a lot of slack for generating more power or torque, it's just a question of having the expertise to find it. A lot of work does go into these chips and remapping programs which is why they can cost upwards of $400 for a quality branded product. Whilst it might only be 5% by the numbers, you likely will notice some of the other effects, like smoother acceleration due to flat-spots in the torque curve being ironed out. Everyone I know who has chipped their vehicles has enjoyed the modification, and relative to what you can do to a car, it's a pretty cheap modification.

Something to be aware of : chipping or remapping your car will likely void any warranty you have on it because you're messing with the onboard computer which in turn is going to adjust the running of the engine to be "different" from factory spec. And by "different", the manufacturer normally means "no warranty". Having said that, some tuner houses have perfected their software to the point where manufacturers own diagnostics computers can't tell that an engine has been remapped. In that case it becomes a moral issue for you - is it invalidating the warranty if they can't tell?

Factory upgrades

Some manufacturers do bolt-on upgrades to their vehicles. For example Dodge introduced a bolt-on upgrade to their SRT-4 Neon in 2003. The kit comes with a modified engine management computer (the whole thing, not just the chip) along with high-flow fuel injectors. The nice thing about doing a factory upgrade is that you know for 100% certain that the parts are going to fit, and are going to work together with each other as well as your car. Since that original upgrade, Mopar have produced a veritable treasure trove of bolt-on upgrades for Dodge vehicles, and with most of them you can maintain some of the factory warranty. Factory upgrades are starting to include chips too now, competing with the aftermarket chipping business. That was a move to counter the warranty problems that some kits caused. Either way, factory bolt-ons are A Good Thing. If you want improved performance but are nervous about third-party products, getting something direct from Dodge, Ford, Toyota, Mazda etc. is a good way to go.

Picture credit: Dodge

High-flow filters

Think of your engine as a breathing machine. It needs to breathe in fuel and air, and it needs to breath out exhaust gasses. Anything that gets in the way of that process is going to impede its ability to breathe. In reality of course, there are plenty of things in the way from air filters and flow sensors in the intake system, to catalysers and bizarre kinks and curves in the exhaust system. By eliminating or reducing these constrictions, you can allow your engine to breathe more easily. Sort of like Nyquil or NightNurse for an engine. By far the easiest and cheapest thing to start with is the air filter. From the factory, air filters are designed to be a compromise of filtering the guck out whilst letting the air through. Aftermarket manufacturers such as K&N and Jamex have been making high-flow air filters for years. The design of the filters is slightly different and they allow more air to pass through the filter whilst still stopping the majority of harmful particles. Again, like all these things, the claims of increased power can be hugely exaggerated. In truth, simply changing the air filter will probably add another 2 or 3hp to your engine. More air going in more easily means the engine management system will adjust the fuelling accordingly and you'll get a better fuel-air charge in the cylinder, resulting in a slight increase in power.

Exaggerating the claims. As with most bolt-on performance parts, the box will always be optimistic with their claims of power increase. A reader sent me a link to this YouTube video testing a VW Golf Mk3, 1.8 litre engine with a stock OEM air filter versus a conical high-flow filter. The filter manufacturer makes the claim that their product will increase the power of your engine by 10%. In this particular test, the horsepower went from 91.9hp with the OEM filter up to 93.6hp with the high-flow filter - a difference of 1.7hp or 1.8%. This is basically an inconclusive result given the measurement and fault tolerance of a rolling-road dyno which is normally in the 3%-5% range. It's certainly not the 10% promised on the box and is closer the 2hp-3hp I would expect from such a filter.  : High flow air filter test.

: High flow air filter test.

Cold Air Induction (CAI) kits

Moving on a step from simply changing the filter, you can then start looking at intake upgrade kits, also known as cold air intake or induction kits (manufactured by companies such as Injen and AEM). The basic idea with these is to make the passage from the filter to the engine less convoluted. When air is forced to go around corners, it causes turbulence which slows down the flow. By trying to make the intake pipes smoother and straighter, the idea is to give the air more chance to get to the engine and less chance of being screwed up in corners with turbulence. Cold-air kits normally remove the factory airbox from the car and poke the air intake into one of the front wings or right up front. The air in your engine bay is hot - really hot - and hot air is not conducive to good combustion. By routing the intake to somewhere where it isn't going to be sucking hot air from under the hood, you get cooler air going into your engine. Because cooler air is denser, you can get a better fuel-air charge into the cylinder than you can by simply changing the stock air filter. Cold-air intake kits can add another 3 or 4hp of raw power to the engine but more often than not, you'll notice an increase in torque lower down the rev range too. The photo to the right was snaffled from a tuning forum but it shows a nice example of a cold-air intake kit once fitted.

Picture credits: K&N, AEM

Throttle body heater bypass

Cold air induction kits work pretty well but you need to do your homework first. A lot of cars have throttle body heaters, whereby coolant from the engine is circulated around the throttle body casing. The idea is to warm up the throttle body to prevent icing in cold weather. The problem is that these systems are hard-wired and don't take account of external air temperature, so even in the heat of summer, hot coolant is routed around the throttle body. This is a problem for CAI kits because you've gone to all the trouble of putting a nice kit in to suck cooler air into the engine, but at the final hurdle it runs through a 75°C throttle body which heats it up again, negating the whole point of the CAI kit in the first place. The solution to this is a throttle body heater bypass, which essentially involves pulling the coolant hoses off either side of the throttle body and patching them together with a length of copper pipe and two hose clamps. When you do this, the throttle body stays at ambient temperature and the CAI kit gets a chance to do its job. The only downside to this is if you live in a cold, humid climate, you might suffer from icing in the winter. But hey - if you do, reconnect the coolant hoses for the winter...

High-flow exhausts

So you've eased the flow of air into the engine, what about the exhaust? Your typical exhaust setup has kinks and bends in it to make it fit the engine compartment and under the car. In some cases these can be smoothed and straightened out somewhat but more often than not, the exhaust has to take the same route as stock. In this case, the best option is for a larger exhaust. Larger diameter exhaust pipes can accommodate more gas flowing through them and hence provide less constriction to the engine when it is blowing out exhaust gasses. Typically a factory exhaust will have two constriction points. There will likely be the catalyser at the front (where the exhaust is hottest and makes the catalyser work best) and a muffler can at the back. High-flow cat-back exhaust systems are so-called because the start at the output of the catalyser and replace all the exhaust from there back. They will have larger diameter pipes and a high-flow muffler at the end. Alternatively you can get header-back exhausts which replace everything from the exhaust header to the back, typically removing the catalyser in the process. These are sometimes affectionately referred to as catless or no-kitty exhausts.

Adding a sports exhaust system like this can add another 4 to 5hp but you need to make sure you get one which is made by a well respected manufacturer with a good warranty. Because of the change in back-pressure, these exhausts can cause erratic engine problems on some cars that rely on a certain amount of back-pressure to operate properly. Note: back-pressure is the natural resistance to gas-flow in a normal exhaust.

The picture here shows an example of a typical factory-fit exhaust on the left versus a high-flow header-back exhaust on the right.

Keying your spark plugs

Picture credit: Pulstar

There's a little known method of squeezing some more efficiency out of your engine, known as spark plug keying. The idea is simple - expose the spark to the incoming fuel-air charge. If the grounding strap on the bottom of the spark plug faces the incoming fuel-air charge, the spark is effectively 'shielded' from the mixture. The image on the left shows a Schlieren photo of a spark emanating from a spark plug tip. You can see the area behind the ground strap doesn't have as much exposure to the spark. Now I know a spark is a spark, and any spark in a fuel-air environment is going to make it burn, but if the spark is facing the intake valves, then there's nothing obstructing the mixture from getting at it. In thousandths of a second, this does actually make a difference to your burn efficiency.

The problem is that when you screw a spark plug into your cylinder head, you have no idea which way the electrode gap is pointing. For best efficiency, it needs to be facing the intake valves or ports as I mentioned above. The solution is pretty simple. Before you install the spark plug, use a marker pen to put a mark on the insulator that aligns with the electrode gap at the bottom of the plug. It's important to use a marker pen and not a pencil because pencil lead is graphite, which conducts electricity. You don't want graphite on the outside of your spark plug insulator!Once the plug is marked, screw it into the cylinder head remembering that you'll need a quarter turn to snug it up. If the mark on the insulator is a quarter turn from facing the intake valves when the spark plug is finger-tight, you'll know once it's snugged down that the gap will be facing the intake valves inside the combustion chamber.

If the mark isn't in the right place, don't go over tightening the spark plug to force it into position! You can get keying kits which are basically replacement crush washers that are slightly thicker or thinner than the standard one. They come in one-third, one-quarter and one-half sizes, meaning that they can affect how far you can screw the spark plug in by the matching amount. So if you finger-tighten the spark plug and the mark on the insulator is facing totally the wrong way, once it's snugged down it will still be a quarter turn away from the intake valves. By changing the crush washer to a quarter-turn crush washer, you'll be able to get an extra quarter turn before the spark plug is tight, which will solve your problem and the electrode gap will now be facing the right way.

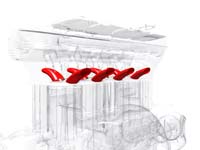

Gas-flowed or polished cylinder heads

If you've changed your intake system and your exhaust system, there is one other place full of nooks and crannies where intake charges and exhaust gasses can get discombobulated, and that is the internal passageways in the cylinder head (shown in red in the picture here). Most heads are cast from dies, a process where molten metal is poured into a sand or ceramic die to create the required shapes. Small bits of swarf and casting anomalies are normally dealt with where they are visible but it is possible that the airways in the head still have some rough surfaces. Gas-flowing a cylinder head involves taking it off the car and refining those airways with one of two methods. The cheaper and more basic method involves manual polishing using different grades of sanding and polishing tools. These are manually run around the passages, smoothing off rough edges and polishing the airways to a chrome-like finish. The more expensive method involves hooking the cylinder head up to a machine which pumps superheated plasma through the airways, which literally melts a thin layer of them off based on the actual flow of the plasma itself (which mimics airflow). Both methods achieve the same results - teflon-smooth air passages for the intake charge and exhaust gasses. Getting gas-flowed heads can add another 11 to 12hp to the engine, plus if you want to put a large-bore exhaust on the car, then the gas flow method can widen the exhaust ports to match.

Rough or smooth? There's an ongoing debate about whether or not polished intakes actually are the best thing for airflow. Some people go with the 'smooth is best' whilst some reckon that a rough intake is better. Chroming or polishing the intakes gives a smooth surface which impedes the airflow less, whilst the rough surface generates turbulent surface 'bubbles' which move slowly, but allow the air on top to skip over them quickly. The point of polished intakes isn't so much to give a smooth surface to the actual intake as it is to make sure there are no kinks, metal seams or casting burrs that will act as a restriction to the airflow.

High-lift or lightweight cams

You can squeeze even more power out of your lump if you change the cam or cams at the top of the engine. Lightweight cams weigh less (duh!) and so impose less mechanical drag on the internal parts of the engine. Less weight and less drag mean less power lost to friction and driving the cams themselves. High-lift cams take a slightly different approach. If you look at the 4 stroke diagram way back at the top of the page, you'll see the lobes on the cams are what force the valves to open. The lobes on a normal cam are egg-shaped. On a high-lift cam, they are more rounded-rectangular shapes. The result is that as the lobe spins round, it begins to open the valve sooner, keeps it open longer and then closes it later. The principal is simple : if the valve is open longer, the engine can suck more fuel-air mix in before the combustion cycle. The picture here shows an (exaggerated) example of high-lift cams. The camshaft on the right shows a regular lobe shape and the one on the left shows how a high-lift lobe might look. The difference is subtle but the one on the left would result in the valve opening sooner, staying open longer and closing later.

If I'm starting to sound like a scratched record, then you've noticed the overriding theme of getting more power - getting more fuel-air mix into your cylinders by any method possible. As they say on naff informercials But wait - there's more! Let the scratched record continue......

Even more power

Water injection cooling

As weird as this sounds, you can actually make most engines perform better in some circumstances by injecting water directly into the fuel-air mixture. It sounds counterintuitive but the principal is really simple. Vapourising water into the fuel-air mix will cause the air to become denser and cooler. Cool, dense air results in a better charge into the cylinder head, which results in a more powerful burn during combustion. This naturally results in more power. Water injection is used on WRC (World Rally Championship) cars but is detrimental to power when the charge air temperature is below 42°C and boost pressure is below 0.6BAR. Because of this a triggering / shut off system is used on some WRC cars that triggers on at 42°C and shuts back off at 38°C, only triggering when boost is above 0.6BAR.

Intercooling

Intercooling takes a slightly different poke at the "cooling the fuel-air mix" equation. Intercoolers are normally found on turbo engines and are designed so that atmospheric air flowing around the outside of them cools the air charge from the turbo inside them. The cooler air for the outside can be direct- or indirect-flow. Direct flow designs have the intercooler mounted at the front of the car in the airflow. Indirect-flow units are mounted somewhere in the engine bay with hoses and scoops to get the air to them.

Water-assisted intercooling

An enhancement to standard intercooling is water-assisted intercooling as found on the Subaru WRX STi. Rather than using water injection into the fuel-air charge, it has an intercooler water spray system that sprays water onto the outside of the intercooler to improve the efficiency of the charge air cooling. The auto version found on the top spec models is ECU-controlled to give 5 second bursts of cooling water when boost is high enough to warrant it. The lower spec versions have a manual switch on the dash that triggers a 5 second burst every time you press the button.

Charge cooling

Charge coolers are a more sophisticated derivative of water-assisted intercooling. Rather than just spraying water around the outside of the intercooler, they have a water jacket around the core with an external water pump and independent radiator. The pump constantly circulates water through the chargecooler jacket and then out to the radiator, keeping the whole unit cool. Chargecoolers work well until the engine starts being more demanding about power - once they get to a certain point, they're overwhelmed by the amount of air being drawn into the engine.

Refrigerated intercooling / chargecooling

Rather than injecting water directly into the air flow, or cooling the body of the chargecooler or intercooler, refrigerated systems force the incoming air over a radiator-like device to cool the air. This heat exchanger is filled with a compressed-gas based and works just like your refrigerator at home. The gas is compressed into a liquid then piped into the heat exchanger. As it turns back into gas, it cools down and hence cools the air flowing over the heat exchanger. The now-gaseous coolant is re-compressed outside the intercooler where it gives off the heat via a secondary radiator positioned in the airflow.

Picture credit: Nitrous Oxide Systems

Nitrous Oxide - NoS

Anyone in the street racing scene, or anyone who saw The Fast and the furious will be familiar with nitrous oxide (N2O), also known by one of the trademarks NoS (Nitrous Oxide Systems - a division of Holley). NoS takes the idea of cooling the inlet charge to extremes. These systems involve an injector unit in the intake system connected via a solenoid release valve to a tank of compressed NoS somewhere else in the car - usually in the boot or trunk. When you push the 'boost' button, the solenoid opens and liquid NoS rushes to the injector. As it vapourises into a gas, it absorbs a phenomenal amount of heat, resulting in a supercooled airflow. At the same time, because it absorbs heat, it splits into oxygen and nitrogen. The normal oxygen content of air is around 20%. With NoS that is pushed up to about 33%. Adding that much oxygen to the intake means you need to also add more fuel otherwise the fuel-air ratio is way off so all NoS kits come with a fuel solenoid and injector too. When you apply the boost, NoS and fuel are forced into a y-nozzle in the airflow just in front of the throttle body. As well as all that plumbing, NoS kits can be enhanced with blow-off valves. If you're sitting at the lights on a drag strip with the NoS system pressurised, it will slowly be evaporating in the system and gaseous NoS is nowhere near as dense as the liquid, compressed form. To get the gaseous stuff out of the line, the blow-off valve is opened by a manual switch in the car to let it out and keep the lines full of liquid NoS. So now you have a highly oxygenated fuel-air mix which is supercooled and thus super dense, being blown into the combustion chamber under pressure, thus forcing more of it in there. The resulting burn is so highly potent that you can easily see a 50hp increase in instantaneous power coming from the engine. Easily.

There are however three obvious downsides. The first is that if your boost pressure is too high, you get way too much NoS into the system and the resulting fuel-air mix can burn so violently that it will blow out your head gaskets and/or melt something important inside the engine. You can safely assume about 20hp increase in power per cylinder before you need to start upgrading to racing parts. The second downside is that the very sudden increase in power from the engine can destroy a non-racing clutch, or if you have a racing clutch, it can torque the drive wheels so much that your tyres simply can't grip and more and you start to skid - not good at speed. The third is that the boost is finite. Once your NoS tank is empty, that's it, no more go-go juice. This is why it's typically only used in street or drag racing because the increase in power is very steep, but very short.

One last thing: however photogenic the neon purple and green gas was coming from the exhausts in The Fast and the furious, that was just Hollywood eye-candy. Your NoS system will not do that.

An Alternative to more power : less weight

Power-to-weight rato

A lot of people think only about power. They want more and more power but they overlook one thing. The speed and acceleration of your car is directly related to the power-to-weight ratio. This is a measure of how powerful your engine is compared to the weight of the vehicle. So a massive V8 lump in a beefy 60's American muscle car might seem like a good idea, but it might easily be outrun by a highly-tuned 2 litre 4-cylinder engine in a super lightweight Japanese car. The actual units of power-to-weight ratio don't really matter, as long as you use the same units when comparing any two vehicles. So you can't use bhp and weight in kilos to measure one vehicle and hp and weight in pounds for the other. So to illustrate power-to-weight ratio, consider the following example. Subaru do several vehicles in their Impreza lineup. From their 2007 range:

Impreza 2.5i 173hp, 3067 lbs kerb weight

Impreza WRX 224hp, 3296 lbs kerb weight

Impreza WRX STi 293hp, 3351 lbs kerb weight

(Kerb weight is the total weight of a vehicle with standard equipment, all necessary operating consumables (such as motor oil and coolant), a full tank of fuel).

You can see as you go up the range, the weight of the vehicles increases, but so does the horsepower. Power-to-weight ratio is a two-sided equation. A vehicle will go faster with less weight, or more or a combination of the two. With the Subaru example, the power-to-weight ratios look like this:

Impreza 2.5i = 1:17.72

Impreza WRX = 1:14.71

Impreza WRX STi = 1:11.43

The figures are easy to come by - divide the power by the weight to get the ratio. The 'to' in 'power to weight' is like the dividing line in a fraction. So 173hp / 3067lbs = 0.0564334, or in standard notation 1:17.72.

You can see that despite the higher-end cars getting heavier, the increase in engine power brings the power-to-weight ratio down so the car becomes quicker. This explains why motorbikes are so quick compared to cars. For example if you compare the 2007 Honda CBR600RR to the 2007 Subaru WRX STi, it becomes readily apparent why the bike will win every time:

Impreza WRX STi = 293hp, 3351 lbs kerb weight = 1:11.43 power-to-weight ratio

CBR600RR = 118hp, 345 lbs kerb weight = 1:2.93 power-to-weight ratio

So it's not that the bike is more powerful - it's not. The engine is only 600cc and it produces almost a third the horsepower of the car. But the bike weighs so much less that the weight side of the equation drops to the point where the ratio plummets.

Weight is everything

So in a car, weight is everything. It can be expensive to start beefing up the engine to give you more power, but it can be really cheap to reduce the weight. As a rough guide, for every 100lbs (45kg) of weight you remove from the average car, you will drop 1/10 second from a timed quarter mile. For the ultimate sports car or street racer, beef up the engine and reduce the weight; increase the power side of the equation and decrease the weight side of the equation and the power-to-weight ratio becomes more favourable.

So how do you reduce the weight of your car. Well again it depends on how far you want to go. If you don't care about carrying passengers, toss out the rear and passenger seats. Don't mind getting a flat and calling a tow-truck? Get rid of the spare tyre and jack. If you're going for a true drag-strip car, take out the glass windows and replace them with plastic ones. Remove the dashboard, carpet, headliner, etc.etc.etc. Beginning to get the idea? There's really no limit to how far you can go. One of the most popular weight-saving mods is a carbon fibre hood. If you're interested enough in this topic to have reached this point on the page, then you'll likely have seen cars with carbon hoods - they're very obvious because the hood is almost always black.

But why this particular item? Well, the hood of your car provides no structural strength, and it has no crash-absorbing properties in a front-end wreck. It's basically an engine cover. Swapping your factory hood for a carbon fibre one can save something like 4kg (8.8lbs) of weight. Doesn't sound like much? Put 4 bags of sugar in a plastic bag and hold it out at arm's length. That's 4 kilos.

People really underestimate the value of weight in a car. It's why race cars are made of sheet aluminium and carbon fibre. It's why they don't have passenger seats. If you're serious about racing your car, shedding weight every bit is as good as adding power. Swap steel wheels for alloys - less unsprung weight and they look better. Swap steel brake discs for carbon-fibre reinforced ceramic ones (standard equipment on some Porsches) and save weight there. Or if you're totally loaded with cash and don't know what to do with it, get pure carbon-carbon discs instead for even more weight saving. Although if you do that, you'll need a healthy disposable income. Carbon-ceramic and carbon-carbon brake rotors do wear annoyingly quickly but you absolutely will stop on a dime.

Like the site? The page you're reading is free, but if you like what you see and feel you've learned something, a small donation to help pay down my car loan would be appreciated. Thank you.

A second alternative to more power : less load on the engine

In an ideal world, the engine in your car would do one thing - propel you forward. In real life of course it's doing a lot more than that. It's driving the alternator to charge your battery and in most cars now, it's also driving the air conditioning compressor (when active). Both of these items increase the load on the engine. As a rough guide, every 25amps of load on the alternator equals 1hp of load on the engine, whilst running the a/c can typically sap 5% of the engine's power. Automobile blog dyno'd a BMW Z4 with the a/c on and off and registered 232hp / 212lb-ft torque with the a/c off and 221hp / 204lb-ft of torque with the a/c on - quite a drop.

So imagine you have a 150hp engine in a vehicle in the summer with the a/c on, running the radio and the seatback DVD player and LCDs for the ankle-biters. You're dropping a couple of horsepower for the electronics in the vehicle (electric power steering, power seats, radio, LT circuit, lights etc) and 7½hp because you're running the air conditioner. Your 150hp engine is now performing like a 140hp engine - you've lost a lot of power there. But what can you do? Well the most obvious thing is turn off the a/c. Unless it's genuinely hot outside, don't use it. For example, in the winter, when you're defrosting the windows on a cold morning - don't turn the a/c on - leave it off. Ok the air won't be so dry but you'll also not be sapping that power from your engine. After that you can look at separate charging and battery circuits for things like the radio or ICE install that only load the engine when they need to charge. Upgrade your alternator to a super lightweight item with professional grade ballbearings on the alternator shaft; this makes the alternator easier to turn and induces less drag on the alternator belt (fractionally).

Grounding kits & noise attenutators / absorbers

You could also look at grounding kits although the jury is still out on whether these actually work or not. The idea with a grounding kit is that you beef up the ground straps in your vehicle to ensure an uninterrupted current flow with less resistance. I'm honestly not sure that this would produce a measurable decrease in load on the alternator but you'll find a lot of these kits being flogged on e-bay. The one thing grounding kits are good for are sorting out the electrics on older cars. For some reason the Mazda RX-7 always seems to benefit from revamping the grounding straps. Bear in mind this isn't going to magically increase the performance of your vehicle though - on an older vehicle you're simply making the electrical system closer to how it was when the car was new.

The other kit you'll see a lot of are noise attenuators. The claim with these is that they 'clean' the 12v electrical signal of the inherent high-frequency electrical noise, to give the engine management system a better chance to read a clean signal from its various sensors. Most of these systems are simply a large capacitor in a plastic box. A capacitor will remove high frequencies, but the frequencies are

dependant on the value of the capacitor and the resistance of the circuit path. Generally speaking, most modern cars already have a suppressor capacitor on the alternator. There's not much harm in adding more, but it would probably be better to fit power filters to each sensor. Without knowing what's inside these devices it would be hard to say if any of them will do what's claimed. Apart from that, if the engine management system is any good it should be able to filter out noisy readings in its software.

Turbos and superchargers

Most people know that a turbo or supercharged engine is more powerful, but do you know why? In simple, sexual innuendo terms, they give more suck before the squeeze, bang and blow of your engine. The basic idea behind both devices is a turbine that sits in the intake airflow. As it spins, it physically sucks more air in than the normal induction of the engine and compresses it further down the line resulting once again in more air in the intake charge, which means better burn which means more power. Both devices are known by the common description of forced induction systems. The difference is the way the two devices are driven.

Turbos

First built in 1925 by Swiss engineer Alfred Buchi, a turbo is normally driven from the exhaust gasses. The faster the exhaust gas passes through one side of the turbo, the faster the exhaust turbine spins and the more air it can force in to the engine using the intake turbine on the other side. This is the source of "turbo lag". When you put your foot down, the engine spools up and produces more exhaust pressure, which spins the turbo and accelerates the incoming air. The lag is the time between putting your foot down and the exhaust gasses getting up enough pressure to make a difference. The advantage of a turbo over a supercharger is that the turbo essentially runs on "waste product". The exhaust leaves the car anyway, so why not make use of it on the way out? A turbo can spin up to 150,000rpm and because it's in the exhaust flow, can reach 800°C in some cases.

The picture here shows a cutaway of a typical turbo. The exhaust gasses flow through the brown section at the back, passing over the blades of the centrifugal turbine and turning the shaft connected to the centrifugal intake compressor in the silver section at the front.

Anti-lag systems

As I mentioned above, turbo lag is an omnipresent problem. Anti-lag systems help to minimise this by keeping a turbo spinning whilst the throttle is closed - a condition which would normally make the turbo spool down. Anti-lag works by bleeding a little air past the throttle and dumping unburned fuel into the turbine housing to keep it spinning. When the power is required, the initial spool-up is already done and the turbo can provide power more quickly, with reduced lag. ALS can add over 200°C to the temperature of the turbo forcing it up over 1000°C.

Dump valves

Most turbo cars have dump valves in the intake system. This is a spring-loaded pressure-release valve. Because of turbo lag, you can take your foot off the accelerator intending to slow down, but the turbo can still be spooling up because of the lag. When this happens, the pressure in the intake manifold rises rapidly because the turbo is now trying to jam more air into the engine than it can handle. When the pressure gets to a certain point, the dump valve pops open and relieves the pressure. It's what gives that satisfying "pffssshhhhhhh" sound when you rev a turbo engine with the car standing still.

Superchargers

Superchargers work slightly differently in that they're normally driven directly from the crank either via a belt or via direct connection to one of the camshafts. With a supercharger, there is little or no lag because you don't have to wait for the exhaust pressure to build up. As soon as the engine starts to spin faster, the supercharger spins faster because of the direct mechanical connection. That advantage is also a disadvantage. Unlike the turbo, a supercharger is imposing a mechanical load on the engine itself, so a percentage of the increase in power is actually taken up simply in driving the supercharger itself. Modern superchargers are quite compact and can sit either on top of, or next to the cylinder head. The most common type, called a twin-screw supercharger, uses a pair of interlocking Archimedes screw compressors (shown on the right) that suck air in and compress it at the same time. Centrifugal superchargers are almost a hybrid between turbos and twin-screw superchargers. They're still driven via a direct mechanical connection, but rather than having the two screws that mesh together, they have a single centrifugal compressor that looks like the intake turbine in a turbo (above). "Classic" superchargers are what you see poking out of the hoods of souped-up 70s Americana with huge air scoops and giant belt-driven compressors. The picture to the left shows a top-mounted belt-driven supercharger.

Exhaust wrap

This little section almost needs to be considered along with turbos, above, because the two typically go hand-in-hand. When gas gets hot, it gets less dense. Less dense means less resistance to flow. It figures, then, that people who are looking at every tiny minutae of performance would want to wrap their exhaust headers. Why? Well exhaust gas exits the combustion chamber extremely hot (duh!) but it cools rapidly as it travels through the exhaust system. In doing so, two things happen. First, the gas becomes more dense and begins to resist flow, and second, as it does this, it disperses heat into the metal exhaust pipes, which in turn radiate the heat into the engine bay, raising the under-hood temperatures. The problem with the gas cooling down is obvious - it begins to slow down and provide resistance in the exhaust system. The problem with the under-hood temperatures going up is that it makes it more difficult for the engine to get a good, cold charge of air. (Colder air is more dense, which means better, more powerful combustion.) This is why you sometimes see vented hoods on cars; they're designed to let the hot air out and keep the under-hood temperatures down. So wrapping the exhaust headers with exhaust wrap helps because it basically insulates the metal exhaust pipes. This means they retain the heat better which in turn means the exhaust gas remains less dense and keeps up it's high flow rate. For turbos, this is a good thing because it means the exhaust reaching the turbo is travelling faster, which means the turbo spins faster, which means more air forced into the engine. Everything is connected, you see? So the ideal system would be a turbo, with wrapped exhaust headers, a vented hood, a cold-air unduction and an intercooler. That combination, whilst expensive, will give the coldest (and thus densest) fuel-air charge into the engine, whilst insulating the exhaust and ventilating the engine bay at the same time.

It's worth pointing out that not all exhaust wraps are made equal. If the wrap insulates too well, then the exhaust pipes get too hot and that can cause all it's own problems from engine bay fires to structural failure of the exhaust or turbo.

Point to note: It's only a rumour that exhaust wrap absorbs water and can encourage your mild steel headers to crumble away prematurely. If anyone tells you this, they're fearmongering.