The car suspension bible - how car suspension works including shocks, struts, springs, raising and lowering your suspension, different types of suspension, all the technologies involved, DIY car maintenance and much more.

The Suspension Bible

Rear suspension - dependent (linked) systems

Solid-axle, leaf-spring

This system was favoured by the Americans for years because it was dead simple and cheap to build. The ride quality is decidedly questionable though. The drive axle is clamped to the leaf springs and the shock absorbers normally bolt directly to the axle. The ends of the leaf springs are attached directly to the chassis, as are the tops of the shock absorbers. Simple, not particularly elegant, but cheap. The main drawback with this arrangement is the lack of lateral location for the axle, meaning it has a lot of side-to-side slop in it.

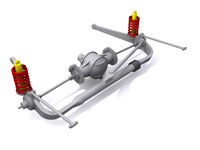

Solid-axle, coil-spring

This is a variation and update on the system described above. The basic idea is the same, but the leaf springs have been removed in favour of either 'coil-over-oil' spring and shock combos, or as shown here, separate coil springs and shock absorbers. Because the leaf springs have been removed, the axle now needs to have lateral support from a pair control arms. The front ends of these are attached to the chassis, the rear ends to the axle. The variation shown here is more compact than the coil-over-oil type, and it means you can have smaller or shorter springs. This in turn allows the system to fit in a smaller area under the car.

Beam Axle

This system is used in front wheel drive cars, where the rear axle isn't driven. (hence it's full description as a "dead beam"). Again, it is a relatively simple system. The beam runs across under the car with the wheels attached to either end of it. Spring / shock units or struts are bolted to either end and seat up into suspension wells in the car body or chassis. The beam has two integral trailing arms built in instead of the separate control arms required by the solid-axle coil-spring system. Variations on this system can have either separate springs and shocks, or the combined 'coil-over-oil' variety as shown here. One notable feature of this system is the track bar (or panhard rod). This is a diagonal bar which runs from one end the beam to a point either just in front of the opposite control arm (as here) or sometimes diagonally up to the top of the opposite spring mount (which takes up more room). This is to prevent side-to-side movement in the beam which would cause all manner of nasty handling problems. A variation on this them is the twist axle which is identical with the exception of the panhard rod. In a twist axle, the axle is designed to twist slightly. This gives, in effect, a semi-independent system whereby a bump on one wheel is partially soaked up by the twisting action of the beam (in effect, the beam becomes it's own antiroll bar). Yet another variation on this system does away with the springs and replaces them with torsion bars running across the chassis, and attached to the leading edge of the control arms. These beam types are currently very popular because of their simplicity and low cost.

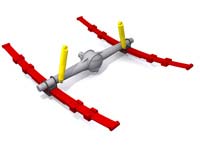

4-Bar

4-bar suspension can be used on the front and rear of vehicles - I've chosen to show it in the "rear" section of this page because that's where it's normally found. 4-bar suspension comes in two varieties. Triangulated, shown on the right here, and parallel, shown on the left.

The parallel design operates on the principal of a "constant motion parallelogram". The design of the 4-bar is such that the rear end housing is always parallel to the ground, and the pinion angle never changes. This, combined with the lateral stability of the Panhard Bar, does an excellent job of locating the rear end and keeping it in proper alignment. If you were to compare this suspension system on a truck with a 4-link or ladder-bar setup, you'd notice that the rear frame "kick up" of the 4-bar setup is far less severe. This, combined with the relatively compact installation design means that it's ideal for cars and trucks where space is at a premium. You'll find this setup on a lot of street rods and American style classic hot rods.

The triangulated design operates on the same principle, but the top two bars are skewed inwards and joined to the rear end housing much closer to the centre. This eliminates the need for the separate panhard bar, which in turn means the whole setup is even more compact.

Derivatives of the 4-Bar system

There are many variations on the 4-bar systems I've illustrated above. For example, if the four angled bars go from the axle outboard to the chassis near the centreline, this is called a "Satchell link". (Satchell is a US designer, who used the above linkage on some of Paul Newmans Datsun road racers some years back.) It has certain advantages over the above examples. Both of the these angled linkages can be reversed to have the angled links below the axle and the parallel links above. The roll centre will be lowered with the angled bars under the axle, a function which is difficult to accomplish without this design. The other variation on the "four bars" not shown are the Watts and Jacobs bar linkages to replace the Panhard rod for lateral positioning. Another linkage is the two parallel bars above the axle and a triangulated link underneath - a design you will find on the Lotus 7 - where the lower link has its base on the chassis and the apex under the differential. Then there is the Mallock Woblink, which could be described as half way between a Jacobs ladder and a Watts link, and makes it possible to place the rear roll centre quite low without sacrificing ground clearance.

Watts links are pretty popular with the hydraulic lowrider/truck bed dancer types. The Jacobs ladder is used almost exclusively on US midget and sprintcar dirt track rear ends. The Mallock Woblink is used mostly on the Mallock U2 Clubman cars in Great Britain.

de Dion suspension, or the de Dion tube

The de Dion tube - not part of the London underground, but rather a semi-independent rear suspension system designed to combat the twin evils of unsprung weight and poor ride quality in live axle systems. de Dion suspension is a weird bastardisation of live-axle solid-beam suspension and fully independent trailing-arm suspension. It's neither one, but at the same time it's both. Weird! With this system, the wheels are interconnected by a de Dion Tube, which is essentially a laterally-telescoping part of the suspension designed to allow the wheel track to vary during suspension movement. This is necessary because the wheels are always kept parallel to each other, and thus perpendicular to the road surface regardless of what the car body is doing. This setup means that when the wheels rebound, there is also no camber change which is great for traction, and that's the first advantage of a de Dion Tube. The second advantage is that it contributes to reduced unsprung weight in the vehicle because the transfer case / differential is attached to the chassis of the car rather than the suspension itself.

Naturally, the advantages are equalled by disadvantages, and in the case of de Dion systems, the disadvantages would seem to win out. First off, it needs two CV joints per axle instead of only one. That adds complexity and weight. Well one of the advantages of not having the differential as part of the suspension is a reduction in weight, so adding more weight back into the system to compensate for the design is a definite distadvantage. Second, the brakes are mounted inboard with the calipers attached to the transfer case, which means to change a brake disc, you need to dismantle the entire suspension system to get the driveshaft out. (Working on the brake calipers is no walk in the park either.) Finally, de Dion units can be used with a leaf-spring or coil-spring arrangement. With coil spring (as shown here) it needs extra lateral location links, such as a panhard rod, wishbones or trailing links. Again - more weight and complexity.

de Dion suspension was used mostly used from the mid 60's to the late 70's and could be found on some Rovers, the Alfa Romeo Alfettas (including the sedans and the GTV) and the GTV6, one or two Lancias a smattering of exotic racing cars and budget sports cars or coupes.

More recently deDion suspension has had somewhat of a renaissance in the specialist sports car and kit car market such as those from Caterham, Westfield and Dax. These all uniformly now use outboard brake setups for ease-of-use, and a non-telescoping tube, usually with trailing links and an A-bar for lateral location (rather than a Watts linkage or Panhard rod.) Whilst a properly setup independent suspension system will always win hands-down on poorly maintained roads, when you get on to the track, the advantage is not so clear cut and a well set up deDion system can often match it turn-for-turn now, espeically for flyweight cars.

Rear suspension - independent systems

It follows, that what can be fitted to the front of a car, can be fitted to the rear to without the complexities of the steering gear. Simplified versions of all the independent systems described above can be found on the rear axles of cars. The multi-link system is currently becoming more and more popular. In advertising, it's put across as '4-wheel independent suspension'. This means all the wheels are independently mounted and sprung. There are two schools of thought as to whether this system is better or worse for handling than, for example, Macpherson struts and a twist axle. The drive towards 4-wheel independent suspension is primarily to improve ride quality without degrading handling.

The eBay problem

This paragraph may seem a little out of place but I have had a lot of problems with a couple of eBay members (megamanuals and lowhondaprelude) stealing my work, turning it into PDF files and selling it on eBay. Generally, idiots like this do a copy/paste job so they won't notice this paragraph here. If you're reading this and you bought this page anywhere other than from my website at car-bibles.com, then you have a pirated, copyright-infringing copy. Please send me an email as I am building a case file against the people doing this. Go to car-bibles.com to see the full site and find my contact details. And now, back to the meat of the subject....

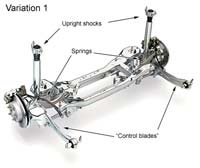

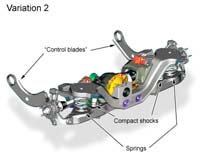

Ford Control Blade™ Suspension

A lot of attention and marketing was paid to Ford about their new Control Blade™ rear suspension when it first came out. Glossy marketing brochures told us how this revolution in rear suspension would make our Ford Focus handle better, grip the road better, and brake better than everything else on the road. What that essentially meant was "we've got a new suspension system". It actually started out its life sometime around 1998 in Ford of Australia and I believe Holden had something to do with it too. Since then its become far more mainstream.

So "Control Blade™" is the snappy moniker that Ford came up with. It sounds good, looks good on paper, and has an aura of 21st century-ness about it. "Blade". Ooh. Cool. But what is "it"?

Control blade is basically an evolution of trailing-arm suspension. The purpose of Control Blade suspension is two-fold. First they wanted to separate the various suspension functions from each other - isolating the handling components from the ride qualiy components. With the springs and shock absorbers being mounted separately, Ford have managed to optimise the function of these components. It's similar in concept to what BMW did with the telelever front suspension on motorbikes (separating braking from suspension forces) only in the Ford system, it separates the springing support of the suspension from the shock reducing functions of the shock absorbers.

Secondly it increases the interior space available in the vehicle. Most suspension systems used in daily drivers have strut towers in the rear of the vehicle - those bumps either side of the boot (trunk). Ford wanted to give more space in the back and needed to find a good way to remove or reduce the size of those towers. With Control Blade™, because the shock absorbers are separated from the springs, it opened up a lot more design flexibility. Ford used a trailing-arm type suspension so that they didn't have swingarms up under the wheel arches and the springs were shortened and moved inboard and underneath. In one variation, the shock absorbers still sit vertically but the space they take up now is hugely reduced because they no longer have the coil springs around the outside. In the second variation the shock absorber is a subminiature unit mounted inboard of the springs underneath the vehicle. The control blades themselves are basically the trailing arms which give lateral support and provide the vertical pivot point for the entire unit.

The Ford spiel says this about Control Blade™: "It has the key function of promoting ride and reducing road noise transmission, while providing the freedom to let the lateral links define toe and camber by absorbing any rearward forces and allowing the rest of the suspension to do it's job uninterrupted. Effectively isolating the handling components of the new IRS from the road noise and impact harshness components of the suspension.". In English? It means better handling and less road noise. Looking at the basic design it's not difficult to see that this system has a much lower centre of gravity than a Macpherson strut (for example). Lower C-of-G in a vehicle is always a good thing. The geometry of the Control Blade™ system also provides significant 'anti-dive' under braking force, which means a the car body will dive less when you jump on the brakes which in turn translates into more well-behaved braking response. Lower C-of-G, less roll and less pitch during braking all add up to better handling.

The images used here are currently from other sources as I've not had the time to render up my own just yet, but they show the basic layout of each variation of control blade suspension and I've annotated them accordingly.

Picture credits: Ford press kit

Aftermarket work on Control Blade™ vehicles.

There's one thing worth noting about this suspension system. Because the spring and shock are in different locations, and because of the reduced or removed strut towers, it makes it very difficult to bolt-on aftermarket suspension kits to these vehicles. For the daily driver, that's probably not an issue but if you're looking at spiffing up the suspension on a Ford Focus for track days or racing, it's not going to be quite so straightforward as it is on other cars. Just so you know.

Repair/rebuild work

When it comes to suspension repair or rebuild, you need to have a reliable source for high-quality suspension parts. Nowadays there are hundreds and thousands of automotive shops full of stuff, from brake parts to side mirrors. However, quantity is not the key point. It is quality that matters first and foremost. Your vehicle's suspension system is meant to provide structural support while maintaining comfortable driving conditions. You can expect only quality, reasonably priced performance suspension parts, lowering & lift kits at CARiD that will take your suspension to a new level. CARiD is a one-stop online store stocking reliable, straightforward solutions for any of your suspension requirements. With CARiD, you cant go wrong.

Like the site? The page you're reading is free, but if you like what you see and feel you've learned something, a small donation to help pay down my car loan would be appreciated. Thank you.