Car Bibles Blog

Observations on Engine Oil Changes in Real-World Automotive Scenarios

The Role of Engine Belts in Automotive Performance

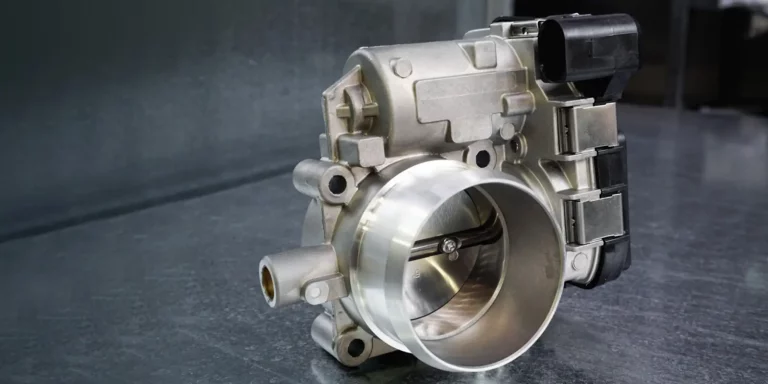

Throttle Position Sensor Issues

Exhaust System Issues

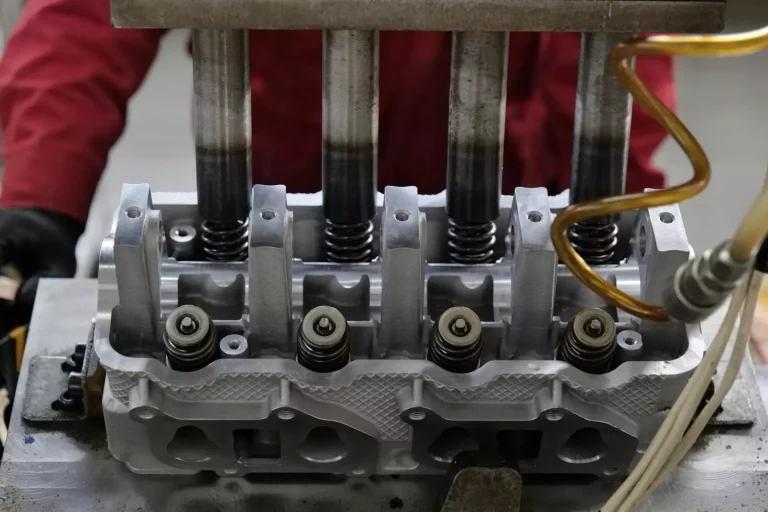

Observations on Head Gasket Sealants

Radiator Bleeding Challenges in the 2013 Ford Escape

Causes of Engine Power Loss and Reduced Fuel Efficiency

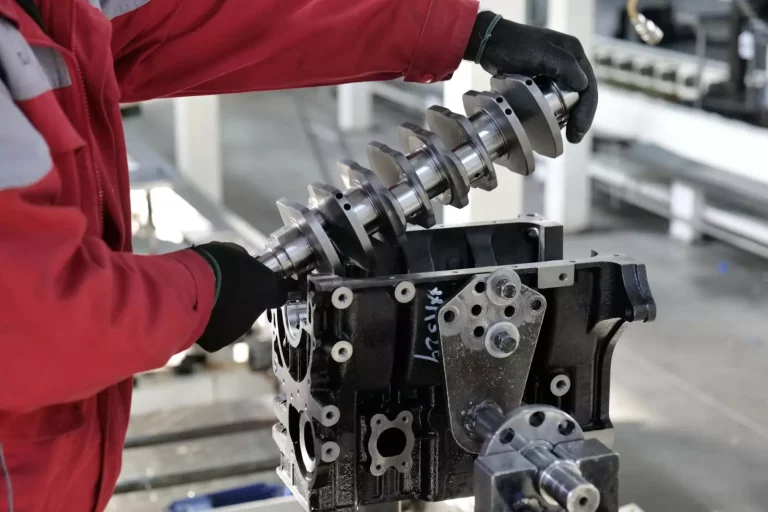

Key Differences Between Camshaft and Crankshaft

Engine Replacement Cost

Thermostat Failures in Automotive Cooling Systems