The modern car engine is nothing less than a marvelous piece of human engineering, combining a variety of scientific disciplines and a fair grasp of the artistic elements of design to give you a very powerful, very elegant, and very fuel-efficient machine. Truly, the modern car engine has come a long way from the very first design of Carl Benz in 1879. The now-relic 1-cylinder, 2-stroke engine has clearly paved the way to more modern car engine designs. And if you love your vehicle, don’t you think you’d want to know more about that big piece of metal block that is driving your car, transporting you to places you’ve never dreamed possible, and giving you pleasures like you’ve never experienced before? Well then, you’ve come to the right place. It doesn’t matter whether you’re an absolute automotive greenhorn or a budding car enthusiast; it pays to learn a thing or two about the machine that is powering your vehicle on a daily basis.

The Internal Combustion Engine

Almost all types of vehicles move by virtue of the power generated by their engines. Just as you need to eat to generate energy needed for all of your physical and physiologic requirements, your car also needs fuel for it to move or run. Without this fuel, it will be virtually impossible for you to move your car. However, that is not all to it. What is important is knowing what happens to the fuel as it enters the engine and how this process can move a vehicle.

The answer lies in the internal combustion engine. To put it very bluntly, the internal combustion engine is what converts the chemical energy provided by the fuel, first into thermal energy, and then into mechanical energy that drives the transmission and the wheels of your car. It is this process of converting chemical into thermal and then into mechanical energy that is at the core of the internal combustion engine. Technically, the process itself is what is called internal combustion.

The principle in action is quite simple, really. When materials that pack tremendous energy, like petrol, are placed inside a tiny, enclosed space where heat is applied, the energy that is packed inside this material expands and is released in an explosive manner. Think of it as a small rubber balloon that you fill with air. It expands and expands until it bursts. If you have an object atop this balloon, you can easily send it flying through the air at tremendous speeds because of the high energy that has been suddenly released by the bursting balloon.

Similarly, the engine is like that. It creates many small explosions within a given span of time. When taken together, these small explosions can amount to an enormous energy that can move your car.

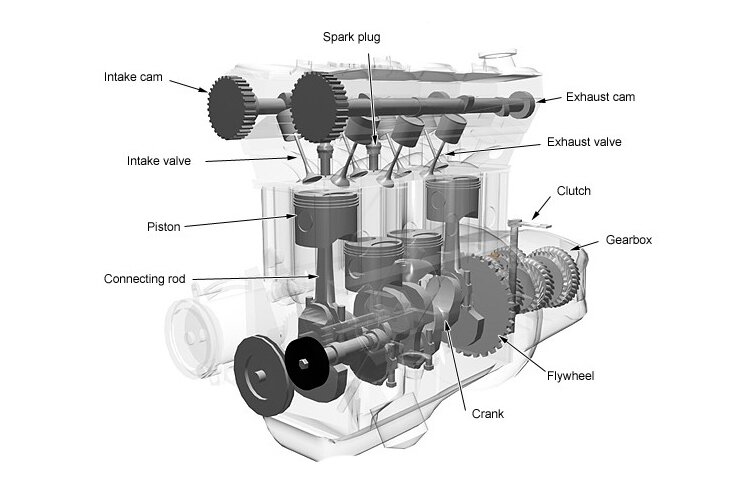

Components of a Car Engine

In a nutshell, a car engine works by converting fuel into motion. It’s as simple as that. However, what should be understood is that this energy – from the gasoline all the way to the final mechanical energy – passes through a variety of parts or components that are crucial to any engine system. Let us thus, next look into the different components of a car engine.

Engine block

Also called the cylinder block, the engine block is essentially the very foundation or the core of your car’s engine. Without it, all other components will simply not have a framework with which to be connected to or mounted on. It is called a cylinder block because of the presence of an unusually big hole or even a series of tubes within the block itself where the pistons will be operating in. The tubes or holes are known as cylinders. Technically, the more cylinders an engine block has the more powerful the engine is. Of course, there are other smaller holes, passageways, or ducts within the block that allow for various critically important fluids to pass through such as the coolant and the oil. The cylinder block is mostly constructed of cast aluminum alloy, although it is not unusual to see some blocks made of cast iron, albeit significantly heavier.

Combustion chamber

Remember what we said about the internal combustion engine being a marvelous piece of technology that transforms chemical energy into mechanical energy? Well, that magic actually occurs in the combustion chamber. This is where your fuel is mixed with air, pressurized, and then ignited to produce those little explosions we talked about earlier. These explosions are filled with so much energy that they move the pistons down in the cylinder block. The combustion chamber is essentially that part of the cylinder in the engine block that is defined by the surfaces of the cylinder wall, the cylinder head, and the top of the piston serving as the wall, ceiling, and floor of the combustion chamber, respectively.

Cylinder head

As we said above, the cylinder head is what forms the ceiling of the combustion chamber. As such, it can be thought of as a lid for the cylinder. Rounded indentations are cast within the cylinder head to provide a small room at the combustion chamber for combustion to occur. The surface upon which the cylinder head comes in contact with the cylinder block is embedded with a head gasket seal to help ensure air-tight environment for combustion to occur. Other parts that are mounted to the cylinder head include intake and exhaust valves, fuel injectors, and spark plugs. These are essentially where all the necessary ingredients for combustion are passed through into the combustion chamber.

Pistons

You can think of the piston like the plunger of a syringe with the syringe acting like the cylinder in your engine block. Pistons are moved by the combustion of fuel in the chamber. As fuel ignites and creates an explosion in the chamber the energy released pushes the piston downward. The downward movement of the piston moves the crankshaft via a connecting rod which is also known as the con rod. The piston is connected to the connecting rod by way of a piston pin while the connecting rod is attached to the crankshaft using a connecting rod bearing.

The body of the piston has between three and four grooves that are fully cast into it. These grooves are what contain the piston rings that actually touch the cylinder walls. There are two types of piston rings which serve different functions. The topmost rings are called compression rings. These are pressed tightly against the cylinder walls to form a very tight seal, allowing combustion to take place without any leak. The bottom ring is called the oil ring which helps prevent the leakage or seepage of oil into the chamber. The oil typically comes from the crankcase underneath it. The oil ring also serves to scrape off excess oil that may be present in the cylinder walls and push it back towards the crankcase.

Crankshaft

Pistons move up and down, so how does that move our vehicle when we want to go in a horizontal direction and not vertical? Well, that job of transforming the up and down motion of the pistons into rotational motion is best left to the crankshaft. Your car needs this rotational motion to turn the wheels of your car. The crankshaft is oriented lengthwise with respect to the engine block, typically located near the bottom of the block. On one end of the crankshaft is a system of rubber belts that connect it to the camshaft. This provides power to other components or parts of your car. On the other end of the crankshaft, a system connects it to the car’s drivetrain which effectively delivers power to your wheels. Oil seals are found at both ends of the crankshaft to prevent oil from seeping or leaking out of the car’s engine.

Protecting the crankshaft is a case which is also located underneath the engine block. The crankcase is what shields the crankshaft and all other critically sensitive components including connecting rods from external debris and dust which can undermine their optimum operation. There is a section on the crankcase that stores the engine oil. This oil pan contains an oil pump and filter that essentially circulates the oil through the crankshaft, cylinder walls, and connecting rod bearings. This helps make it easier for the piston stroke to move along the cylinder.

The crankshaft also contains balancing lobes, located anywhere along the length of the crankshaft. These lobes serve to balance the crankshaft so that it doesn’t put undue stress and vibration in the engine as the crankshaft rotates. There are main bearings, too, located along the length of the shaft. These provide a much smoother surface between the cylinder block and the crankshaft, allowing for a more efficient rotation of the latter.

Camshaft

For the engine to work, it needs precision when it comes to the addition of fuel, the mixing of air, the application of pressure, and the delivery of an electric charge. Any miscalculation in any of these components can lead to a loss of power in the engine or even engine damage. That is why the function of the camshaft is very important. It serves to ensure the precision opening and closing of both the intake and the exhaust valves to allow for timely combustion, ensuring optimum engine performance. The camshaft works in tandem with your car’s crankshaft through the use of a timing belt. It is for this reason that many look at the camshaft as the engine’s brain.

Camshafts are located just above the crankshaft. Inline engines usually have a single camshaft that manages both the intake and the outtake valves. In a V-configuration engine, however, one camshaft will be exerting control on the valves located on one side of the configuration while another camshaft will be handling the valves on the other side. There are also certain V-configurations that provide for 2 separate camshafts for each cylinder bank. Recent engine innovations now use a single camshaft to work with both the intake and exhaust valves, including variable valve timing applications.

Timing system

It is critical that the crankshaft and the camshaft get their acts together to help provide for optimum engine performance. That is why they have to communicate with one another. The only way they can do this is through the timing belt, also called the timing chain, often depending on the material used. There really is nothing too complex about the role the timing chain or belt has in engine performance. It simply needs to make sure that the camshaft and the crankshaft are in the same position relative to each other every time, all the time. If they do not synchronize, then the engine simply will not run or worse create chaos in movement causing total engine failure and damage.

Valve train

Located atop the cylinder head is the engine’s valve trainwhich consists of the valves, lifters, rockers, and arms. Technically, this mechanical system in your engine is what precisely controls the efficient functioning of the engine valves.

Valves

Think of the valves as your nose. You need to breathe in air to feel alive; you also need to exhale so that the metabolic waste products don’t accumulate inside your body. While the analogy may miss the point, valves are the openings upon which air and fuel are injected into the combustion chamber and these are also the openings that direct the byproducts of combustion outwards. Those valves that allow fuel and air into the chamber are called intake valves while those that bring the byproducts of combustion outside are known as exhaust valves. Together they form a more efficient means of using the energy stored in fuel and managing the by-products of combustion in the form of exhaust.

Normally, one cylinder contains one each of intake and exhaust valve. However, a majority of high performance vehicles will have 2 intake and 2 exhaust valves for each cylinder, bringing the number to 4. Still, there are those that aim to make a compromise between a 2- and 4- valve per cylinder configuration by providing for 3 – 2 intakes and 1 exhaust. Generally, the more valves per cylinder the better it is when it comes to engine performance since it allows for the more efficient ‘breathing’ of the engine.

Rocker arms

From the name itself, ‘rocker’, you can think of it as a see-saw. The rocker touches the cams of the camshaft such that if one cam pushes one end of the rocker up, the opposing rocker end will push down on the stem of the valve, opening it so that air will enter or that exhaust will move out.

Pushrods and lifters

There are some types of engines, especially those that are classified as overhead camshafts, which do not allow for the contact between the lobes of the camshaft and the rocker. In such cases, lifters and push rods are used to either open or close the valves, respectively.

Fuel injectors

We know that air and fuel need to be present in the combustion chamber to generate the explosive energy that will move the pistons and turn the crankshaft. Fuel must thus be pushed into the combustion chamber where it will be mixed with air. In the past, this was accomplished by the carburetor. Today, the delivery of fuel into the combustion chamber is accomplished by the fuel injectors. Currently there are three types of fuel injection systems. These include the following.

- Direct fuel injection – In this system, each cylinder comes with its own fuel injector. Fuel is sprayed directly into the chamber.

- Ported fuel injection – In this type of fuel injection, fuel is sprayed into the intake manifold which is located just outside the intake valve. As the valve opens, fuel and air enter the chamber at the same time.

- Throttle body fuel injection – One can look at the throttle body type of fuel injection as a more advanced form of carburetor type of fuel delivery. A single fuel injector connects to the throttle body where air and fuel mix. The air-fuel mixture is then injected through the intake valves and into the cylinders.

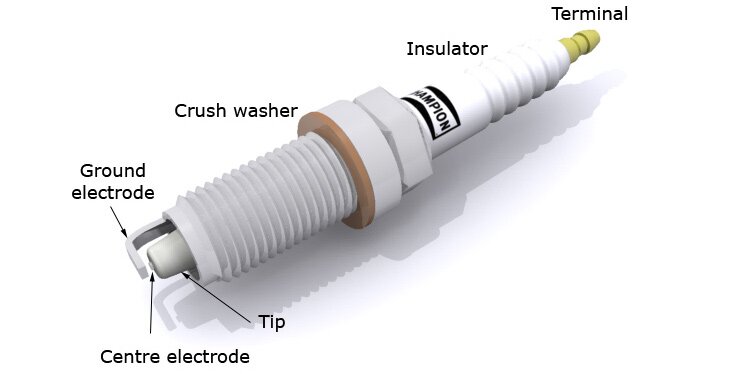

Spark plugs

Even if you have a good mixture of air and fuel, you will need heat to produce fire. This is provided by the spark plug. Each cylinder contains a spark plug located above the cylinder. An electrical charge is delivered by the spark plug, igniting the compressed mixture of air and fuel. This creates the mini explosion that we have been talking about, releasing enough energy to move the pistons.

Let us try to summarize what we know so far.

- Fuel and air are mixed and delivered to the combustion chamber through the intake valves.

- As the mixture is compressed and heat is applied by the spark plug, mini explosions occur which move the pistons.

- The byproducts of the combustion are then moved out of the system through the exhaust valves.

- Meanwhile, the movement of the pistons turns the crankshaft.

- The front-end of the crankshaft runs other parts of the vehicles.

- The back-end of the crankshaft runs the drivetrain that puts power to the wheels.

And that’s how a car engine works. Of course, embedded in all of these steps are the functions of the various other components of the engine.

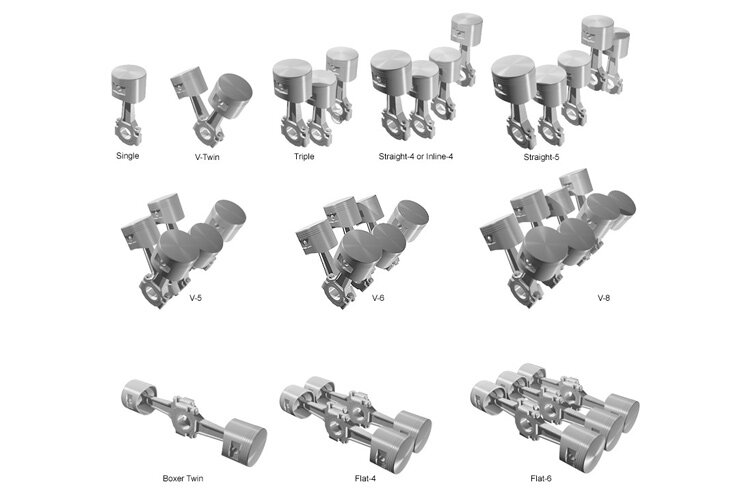

Engine Layouts

You’ll be forgiven for thinking that there are only two types of engine configurations or layouts in the automotive world today: the V and the straight or inline. We’re sorry to burst your bubble but there are clearly more than these two configurations. Here we’ll take a closer look at each of them.

The inline or straight

As the term implies, the arrangement of the cylinders are in a pretty straightforward linear fashion. Most cars today use this configuration for a variety of reasons. The cylinders are located directly above the crankshaft. Examples of these are the ubiquitous inline-4 and the more European standard straight-6. As you have guessed it, an inline-4 will have 4 cylinders arranged in a straight line. A straight six will have 6 cylinders. Audi and BMW are fanatics when it comes to the straight-6.

The advantages of a straight or inline configuration include the following:

- Compact and lightweight

- Better fuel economy

- Ideal for modern front-wheel drive cars

- Easily tunable

- Easier to maintain

The straight or inline layout does have caveats, though.

- Limited maximum size

- Higher center of gravity

- Less rigid than other engine configurations

The V configuration

This is perhaps one of the most famous engine configurations when one talks about power. It’s what separates American muscle cars and exotic sports cars from those that are only dressing up the part. A common crankshaft provides the anchor for the cylinders that are oriented in a V at different angles, although a 90-degree orientation is quite common in the racing circuit. The engine typically contains a set number of cylinders which typically comes in a V label. For instance, a V6 means you’ve got 6 cylinders while a V8 will have 8 cylinders and so on and so forth.

But why would you want a V configuration in your engine? Here’s why.

- Highly compact dimensions

- Allows for greater number of cylinders

- More powerful, thanks to higher displacement cylinders

- Accommodates higher compression

- Excellent levels of refinement

- Very powerful engine

However, do understand that the V configuration has its drawbacks, too.

- More complex

- More expensive to maintain

- Very heavy

The flat or boxer configuration

Popularized by the people’s car, the VW Beetle, the flat or boxer engine has clearly fallen out of favor from many of the leading car manufacturers, although Porsche and Subaru still make their engines in this configuration. The boxer is characterized by pistons that are horizontally opposed to each other, where the pistons imitate the movement of a boxer’s hands hence the name. The configuration makes the engine wide and low with a common crankshaft sandwiched by 2 cylinder banks that house the horizontally opposed pistons.

The advantages of the flat or boxer include:

- Low center of gravity

- Better handling

- Excellent balance, translating to smoother operation

- Minimal power loss

- Less weight and strain on the crankshaft

- Perfect for motor racing

The disadvantages include:

- Unusually wide

- More raucous than a straight or inline

- More complex

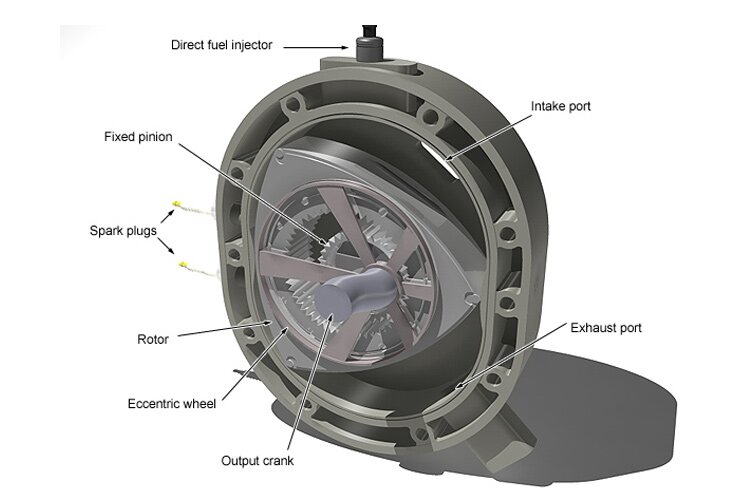

The Wankel or rotary engine

Prior to 2012, the Wankel engine proved to be one of the most innovative engine design configurations courtesy of Mazda. One of the most alluring things about the Wankel is that it comes with very few moving parts giving it a highly compact design. Unfortunately, it performed miserably in pollution and consumption norms so it never really did go beyond the Mazda platform. Instead of pistons, the Wankel utilized rotors to draw power from the combustion chamber. Additionally, instead of the crankshaft rotating, it was the entire cylinder block that actually moved around the crankshaft. An eccentric shaft is surrounded by a 3-sided symmetrical central rotor which allowed for greater efficiency since a single rotation of the rotor already accomplished the full 4 strokes of combustion engines.

The Wankel provided the following advantages.

- Exceptionally high ratio between power and weight

- Very few moving parts

- Simple design yet efficiently engineered

- Very refined

- High revving

It had serious flaws, nonetheless.

- Higher gas emissions

- Excessive heat

- Requires more frequent engine rebuilds because of the failure of the rotary seals

The W- engine

If you love the Bugatti Veyron, then you’ll love the W engine configuration. This is a very uncommon engine configuration pioneered and exclusively produced by Volkswagen. You can look at it as a combination of 2 V-engines arranged in a rather tight position. This gives the cylinders a peculiar W-arrangement. There are 4 cylinder banks on a single crankshaft. The unique arrangement of the cylinders allows the W-engine to obtain a very compact design despite the fact that it can house more cylinders than any other configuration. Unfortunately, this also makes it very complicated to maintain, not to mention exceptionally costly. Because there are more cylinders in a tighter configuration, operating temperatures tend to be unusually high.

The Difference between 2 Stroke and 4 Stroke

Engines are classified not only according to their configuration or layout; they can also be classified according to the power or thermodynamic cycle that is performed by the pistons. This is typically described as the number of strokes needed to complete a cycle. The two more common types of thermodynamic cycles include a 2-stroke engine and a 4-stroke engine. We will try to differentiate between these two systems before we take a more detailed look into how each system works.

The 2-stroke engine

As the name implies, this type of engine requires two strokes to complete a thermodynamic cycle. These are typically seen in motorcycles as well as chainsaws and lawnmowers, among others. A thermodynamic cycle is completed for every revolution of the crankshaft.

- 1:1 power stroke to crankshaft revolution

- Requires a lighter flywheel

- Engine operates balanced because of the 1:1 ratio of power stroke to crankshaft revolution

- The engine is typically lighter

- Engine has a simple design because it doesn’t require any valve mechanism

- Less expensive than a 4 stroke engine

- More mechanically efficient because of less friction

- Engine is typically air-cooled

- Engine runs hotter

- Less powerful

- Less fuel efficient

- Noisier

- Less thermally efficient

- Requires more lubrication

- The engine consists of an inlet port and an exhaust port

- Greater incidence and more frequent wear and tear

The 4-stroke engine

This type of engine requires 4 strokes to complete a thermodynamic cycle which is equivalent to 2 revolutions of the crankshaft. These are used in automotive applications such as buses, cars, and trucks, among others.

- 1:2 ratio; requires 2 crankshaft revolutions to produce a power stroke

- Requires heavier flywheel

- Engine typically runs unbalanced because of the disproportionate revolution of the crankshaft relative to the completion of a single thermodynamic cycle

- Engine is relatively heavy and comes with a complicated design, thanks to the inclusion of valve mechanism

- More expensive than a 2 stroke engine

- Greater friction because of the sheer number of moving parts

- More powerful

- Engine operates a lot cooler than a 2 stroke engine

- The engine is water-cooled

- More fuel efficient as it allows for the complete burning of fuel

- Requires more space in the engine bay

- Requires complicated lubrication

- Engine operates with less noise

- Engine has valves for intake and exhaust

- More thermally efficient

- Consumes substantially less lubricating oil

- The moving parts undergo less wear and tear

To simplify further,

- 4 stroke engines – For automotive vehicles like cars, trucks, buses, vans, SUVs.

- 2 stroke engines – For motorcycles, scooters, mopeds, and the like.

How 2 Stroke Engines Work

In the preceding section, we differentiated between a 2 stroke engine and a 4 stroke engine. For simplicity’s sake, 2 stroke engines are small and are best reserved for smaller vehicles like motorcycles, mopeds, and even power tools like lawn mowers. But why is it that this type of engine is only used by these types of machines? Let’s look at how the 2 stroke engine works.

As we already mentioned above, the 2 stroke engine only requires 2 strokes to complete one power cycle or one thermodynamic cycle. This means that it only needs one revolution of the crankshaft to complete a power cycle. As such, both the cylinder and the crankcase have to be employed to allow for the completion of the cycle in just 2 strokes. Here’s how.

Intake

As the piston moves upward, a vacuum is created in the crankcase. This effectively draws the fuel and air mixture towards the crankcase through a poppet intake valve or a rotary valve seen in many 2 stroke engines today.

Compression by the crankcase

As the piston moves downwards the pressure inside the crankcase increases, forcing the poppet valve or rotary valve to close. This compresses the fuel and air mixture during the remainder of the downward stroke.

Transfer and exhaust

As the stroke nears its completion, the intake port is exposed by the piston. This allows the compressed mixture of fuel and air to be pushed towards the main cylinder, passing around the piston. This also pushes the exhaust gasses towards the exhaust port. Sadly, some of the fresh mixture of air and fuel typically gets expelled, too.

Compression

The piston rises to compress the air/fuel mixture. Another intake stroke is being initiated beneath the piston while this is occurring.

How 4 Stroke Engines Work

The 4 stroke engine works essentially in the same way as a 2 stroke engine except that it requires 2 revolutions of the crankshaft to complete a single power cycle or thermodynamic cycle. This means that you have an upward and a downward stroke for each revolution and you need two sets of the upward and downward movement of the piston to create a power cycle. Let’s take a closer look.

Intake

As the piston moves downwards through the cylinder, it creates a vacuum which effectively draws air into the cylinder. The air enters the cylinder through the intake valve. At the same time, fuel is sprayed into the cylinder by the fuel injector to create an air and fuel mix.

Compression

To compress the air and fuel mixture the intake valves close and the piston is moved upwards by the crankshaft.

Combustion

As soon as the piston reaches the top of the cylinder, the sparkplug emits an electric discharge to ignite the fuel-air mixture. Because of the resulting explosion or combustion, the tremendous energy forces the piston towards the lower portion of the cylinder again.

Exhaust

As soon as the piston reaches the cylinder’s bottom, the exhaust valves open. This creates a pressure differential whereby the piston is moved upwards again. This upward movement of the piston is what expels the exhaust gases from the cylinder.

2 and 4 Stroke Diesel Engines

Diesel engines are pretty much similar to gasoline engines since they are still internal combustion engines. You will still need to mix air and fuel and apply some heat to allow the mixture to explode, releasing its energy. This energy is then used to run the vehicle. However, unlike gasoline engines, diesels are much simpler. Here’s how they work.

- Air enters the cylinder and is compressed by the pistons by up to 25 times. By comparison, the compression of air in a gasoline engine is roughly 1/10 the volume of air. So if you’re introducing 100 cc of air, a gasoline engine will only compress this to about 10 cc. By contrast, the diesel engine will compress about 2500 cc into the same tight space. We know in physics that compressing such a huge volume of air into a very tiny space will agitate the gas molecules, creating friction. And whenever friction is involved, heat is generated. This makes the compressed air of diesel engines extremely hot, typically reaching no less than 1000O

- A mist of fuel is then sprayed into this super-hot compressed air. This essentially ignites the fuel without the need for a spark plug. This is what makes it exceptionally efficient since the combustion is no longer dependent on the heat provided by a spark plug. The air can get extremely hot that the mere introduction of highly controlled fuel is enough to cause spontaneous combustion.

- The combustion pushes the piston downwards, turning the crankshaft, and delivering power to the wheels.

- As the piston returns, it pushes the exhaust gases outwards through the exhaust valve.

Technically, the process is similar to a gasoline engine except for three very important differences:

- Air must be compressed first to substantially high levels before fuel can be added

- Substantially higher compression of the air drawn into the cylinder

- Spontaneous combustion resulting from the exceptionally high temperature of the compressed air

So what is the difference between a 2 stroke and a 4 stroke diesel engine? Like gasoline engines, the difference lies in the number of power strokes with each revolution of the crankshaft with the 2-stroke offering a 1:1 ratio while the 4-stroke giving a 1:2 power cycle-to-crankshaft revolution ratio.

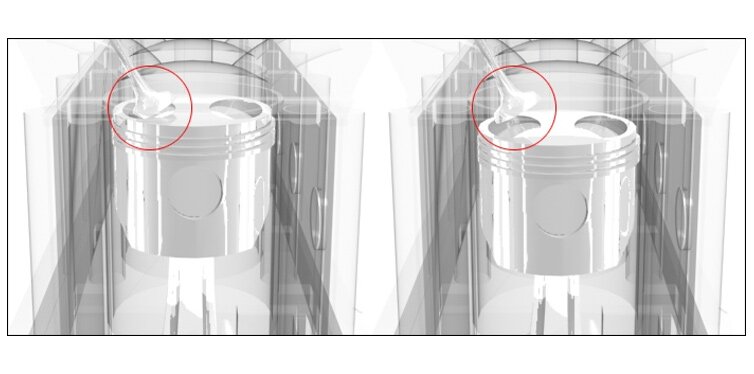

Interference vs. Non-Interference Engines

Engines can also be classified according to the amount of clearance that the pistons have relative to the valves. These are called interference and non-interference engines.

Interference engines

These are engines that have very little clearance or space between the pistons and the valves. It also called as the ‘destructive head’ type of engine since a failure in the timing chain or timing belt can lead to damage to the valve. These engines depend on fully functioning timing belts, chains, or gears to help prevent the piston from ever striking or getting in contact with the valves. The timing system must ensure that the valves are completely closed as soon as the piston is near the top dead center of the cylinder. While these engines may be a bit destructive, they are commonly used in 4 stroke engines because of the higher compression ratio that it affords the engine. It is thus, imperative that meticulous preventive maintenance of the various timing components as well as the camshafts be instituted to prevent major internal damage to the engine.

Non-interference engines

The clearance or space between the valves and the pistons in these types of engines are larger. This helps ensure that the piston will not strike the valves even if the latter are at a fully open position. While it may not lead to major internal engine damage, it can nevertheless, lead to issues of safety and convenience as your engine will simply stop running.

Understanding how your car’s engine works is crucial to keeping it in tip-top shape. Regardless of the type of engine that your car has, the fundamental principle is relatively the same throughout. Your engine needs to convert the chemical energy contained in your fuel into thermal energy to push a variety of mechanisms creating mechanical energy in the process. This, in turn, is what moves or runs your car.

To help maintain your engine to its peak performance our buying guides to the best car battery, oil additives, octane boosters and synthetic motor oils.

Sources:

- How Does a Car Engine Work? – U.S. News

- How Car Engines Work – howstuffworks

- Gearhead 101: Understanding How Your Car’s Engine Works – Art of Manliness

Best Car Safety Jack Stands (Review & Buying Guide) 2019

The Best Engine Air Filters (Review & Buying Guide) in 2019

The Best Car Brakes (Review & Buying Guide) in 2019

The Best Trickle Charger (Review & Buying Guide) in 2019

Comments