The engine oil Bibles - everything you need to know about engine oil including viscosity, friction reducers, additives, oil types, sludge, SAE and API classifications and ratings, what all the codes and markings mean, how your engine oil works, how to keep your engine running at peak fitness and much more.

The Engine Oil Bible

"High mileage" oils.

More and more oil companies are coming out with "high mileage" oils, some recommended for engines with as few as 75,000 miles on them. So what is a "high mileage" oil? Very generally speaking, these oils have two additives in them that are more suited to older engines. The first is normally a burnoff-inhibitor which helps prevent the oil from burning off if it gets past an engine seal into the combustion chamber. The second is a "seal conditioner", the exact makeup of which can vary, but it's designed to soak into seals such as head- and rocker-cover gaskets and force them to expand. Thus if one of the seals is a bit leaky, the seal conditioner will attempt to minimise the leak.

A few readers who have experience with high mileage oils have e-mailed, passing on various tales from it being the miracle cure to it making no difference at all. The general rule-of-thumb though should be "if it 'aint broke, don't fix it." Just because an engine has over 75,000 miles on it, doesn't automatically mean it needs a high mileage oil. Is the exhaust sooty or smokey? Are there noticeable oil leaks? Is the engine consuming oil? If the engine is working fine, the exhaust is clean and there's no noticeable problems, chances are it doesn't need high-mileage oil.

What about own-brands?

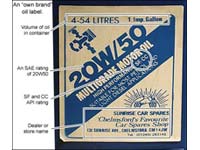

The big names in oil can be expensive - a cheaper option can be own-brand oils. These are usually badged oils from one of the larger companies but sold without the name, making them cheaper. Check the standards and grade ratings on the pack first! The example on the left is a local store in Chelmsford in England who sell their own label oil which is bottled for them by a volume retailer. The label tells you all you need to know.

Viscosity and Viscosity Index (VI).

The proper viscosity is the single most important criteria of a lubricating oil. The basic performance of machinery is based on the viscosity of the lubricant. Viscosity is the resistance to the flowability of the oil. The thicker an oil, the higher its viscosity. The chart on the right shows a rough guide to ambient temperatures vs oil viscosity performance in both multigrade (top half) and single grade (lower half) oils.

Multigrade oils work by having a polymer added to a light base oil that prevents the oil from thinning too much as it warms up. At low temperatures, the polymers are coiled up and allow the oil to flow as it's low number (W number) indicates. As the oil heats up, the polymers unwind into long chains which prevent the oil from thinning as much as it normally would. The result is that at 100°C, the oil has thinned only as much as its higher rating. Think of it like this: a 10W30 oil is a 10-weight oil that will not thin more than a 30-weight oil when it gets hot.

The viscosity index of a lubricant is an empirical formula that allows the change in viscosity in the presence of heat to be calculated. This tells the user how much the oil will thin when it is subjected to heat. The higher the viscosity index, the less an oil will thin at a specified temperature. Multi-viscosity motor oils will have a viscosity index well over 100, while single viscosity motor oils and most industrial oils will have a VI of about 100 or less.

Viscosity and oil weight numbers is quite a nauseatingly detailed topic. So if you're curious about why a 15W50 oil is so-called, then put on the geek shield and pop over to the Viscosity Page.....

Servicing and checking

For God's sake don't skimp on either of these. You can never check your engine oil too often. Use the dipstick - that's what it's there for - and don't run below the 'min' mark. Below that, there isn't enough oil for the pump to be able to supply the top of the engine whilst keeping a reserve in the sump. All oils, no matter what their type, are made of long-chained molecules that get sheared into shorter chains in a running engine. This in turn means that the oil begins to lose its viscosity over time, and it uses up the additives that prevent scuffing between cams and followers, rings and cylinder walls etc etc. When this happens, fresh oil is the key. Don't worry about the engine oil turning black. It will lose its golden-brown colour within a few hundred miles of being put in to the engine. That doesn't mean it's not working. Quite the contrary - it means it is working well. It changes colour as it traps oxidised oil, clots and the flakes of metal that pop off heavily loaded engine parts. Just don't leave it too long between oil changes.

So how often should I change my oil?

![[oilchange]](images/oilchange.gif)

You can never change your engine oil too frequently. The more you do it, the longer the engine will last. The whole debate about exactly when to change the oil is somewhat of a grey area. Manufacturers typically indicate every 10,000 miles or so. Your mate with a classic car says every 3,000 miles. Ole' Bob with the bad breath who drives a truck says he's never once changed the oil in his ve-hicle. Fact is, large quantities of water are produced by the normal combustion process and, depending on engine wear, some of it gets into the crank case. A good crank case breathing system ensures the water gets removed from there PDFQ, but even so, in cold weather a lot of condensation will take place. This is bad enough in itself, since water is not noted for its lubrication qualities in an engine, but even worse, that water dissolves any nitrates formed during the combustion process. If our memory of chemistry serves us right, that leaves a mixture of Nitric (HNO3) and Nitrous (HNO2) acid circulating round the engine! So not only does it suffer a high rate of wear at start-up and when the engine is cold, it suffers a high rate of subsequent corrosion during normal running or even when stationary.

The point we're trying to make is that the optimum time for changing oil ought to be related to a number of factors, of which distance travelled is probably one of the least important in most cases. Here is my selection in rough order of importance:

- Number of cold starts (more condensation in a cold engine)

- Ambient temperature (how long before warm enough to stop serious condensation)

- Effectiveness of crank case scavenging (more of that anon)

- State of wear of the engine (piston blow-by multiplies the problem)

- Accuracy of carburation during warm-up period (extra gook produced)

- Distance travelled (well, lets get that one out of the way)

If very clever (or obsessive) owner could probably come up with a really clever formula incorporating all those factors. However, we would give 1, 2, and 3 equal top weighting. Items 1 to 3 have to be taken together since a given number of "cold" starts in the Dakar in summer is not the same as an equal number conducted in Fargo in January. The effect in either case will be modified by how much gas gets past the pistons. What we are really after is the severity and duration of the initial condensation period. All other things being equal, that will indicate how much condensate will be produced and we would suggest that more than anything else determines when the oil should be dumped.

Dammit - get to the point already!

Hang on a moment - if you really want the answer, there's a couple more factors that need to taken into account: Crank-case scavenging (that's the clever term for sucking the nasty fumes back out of the crank-case) - or lack of it - is a crucial multiplying factor affecting all the other items listed above. As an example, the worst we've heard of was a Ford Fiesta of the mid 70s or so. Its crank-case fume extraction was via a tiny orifice directly into the inlet manifold which obviously could not handle any significant volume of crank-case fumes without upsetting the carburation. The car in question had been used almost exclusively for 5 mile journeys to/from work, shopping etc, and it had always been serviced "by the book".![[averagecar]](images/notfamilycar.gif) Despite (or because of) this, the engine was totally buggered at 40,000 miles. Alternatively its possible to find a car that by virtue of excellent crank case fume scavenging could tolerate many more cold starts than one without.

Despite (or because of) this, the engine was totally buggered at 40,000 miles. Alternatively its possible to find a car that by virtue of excellent crank case fume scavenging could tolerate many more cold starts than one without.

Taking all these into consideration, our philosophy would be to totally ignore the distance and change the oil twice a year - about November and March. Move these dates a bit according to the severity of the winter. An average family car will do around 14,000 miles per year and about 2/3 of that will fall in the March - November period. At the end of that period, the car will be getting close to the manufacturer-recommended oil change interval - but all that distance will have been done at reasonable temperatures, including long distance runs during vacations and good weather. During the November to March period it may accumulate only two or three thousand miles, all low temperature starts and mostly short runs.

Around 1995, an article in the ANWB journal (ANWB is the Dutch equivalent of the AA - or the AAA in the American case) reached more or less the same conclusion that distance was not very important. In their case they applied this to their road service fleet, which once started in the morning never got cold. In effect, they hardly ever changed the oil. It worked out at something like 30,000 miles between oil changes. They also had some kind of water or acid indicator attached to the end of the dipstick and went by that rather than distance.

That's a politician's answer - talk about dodging the entire issue!

![[8000]](images/8000.gif)

Dodging the issue? We don't know how far a car is driven in a year, where it lives, the driving style of the owner, and many other things, so we can't tell what's right for any particular car. This author changed the oil and filter in his 1985 Audi Coupe every 5,000 miles. It had done over 150,000 miles when it was finally sold, wasn't leaking and didn't consume any oil. My Subarus got oil changes at 10,000 miles but were newer cars in a warmer environment. My VWs got oil changes at 8000 miles or so. If you must have a figure, then 8,000 is it.

Maintenance minders - when the car tells you when to change the oil

![[maintenance required]](images/maintreqd.gif)

A lot of cars now come with maintenance minders - inbuilt systems designed to tell the driver when to change the oil rather than leaving it to guesswork. First generation systems were nothing more than mileage counters. When the car reached an interval of 3000 miles, the light came on. Now they're more involved. The system typically monitors driving style (in terms of how long is the throttle open for any given duration of driving), air intake and external temperatures, coolant temperatures and variations and engine timing (determined by load on the engine and octane of fuel). There's a clever formula that each manufacturer keeps to themselves that can take in any or all of these factors (and probably more) to determine how fast an average oil will be ageing in the engine. When it gets to the point where the system decides that time is up, a light will come on on the dash - typically "Maint Reqd" or "Service Reqd" (Note - this is NOT the "check engine" light). On some cars the various trip computer settings can be cycled through to see an oil life remaining readout - normally given as a percentage. This is a convenience function so the driver can tell at any point in time roughly how much longer to before an oil change. That's useful for planning road trips - don't go on a 2000km trip if the oil life remaining indicator shows 10%. On cars with these systems, I would defer to the onboard computer rather than trying to work it out for yourself. When the system tells you to change the oil, just do it. I've found that my 8,000 mile guesstimate above is pretty close to when the maintenance minder in my cars has indicated an oil change was due.

What else happens when the oil is changed then?

Engines pump about 10,000 litres of air for every litre of fuel consumed, and along with all that air, they suck in plenty of dirt and grit. A good air filter will stop everything bigger than a micron in diameter - everything smaller mostly just floats around harmlessly in the 0.001 inch minimum thickness oil films that separate all the moving parts. Despite all of this, there will always be submicron particles that get in and there will be places in the engines oilways where they will gather. Every time the oil is emptied from the sump, the fine grit is being drained with it.

Checking the engine oil, and topping up.

Note that this section only applies to wet sump engines - the type found in most consumer vehicles. For more info on sump types, see Wet sumps vs. dry sumps below.

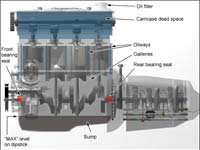

To a lot of people, this little section could be categorised by the rearranging the words "granny eggs teaching suck your to". But it is surprising the number of people that don't know how to do even this basic task. When checking the level of oil in the engine, the car should be on a level surface, and should be relatively cold. Some people will insist in keeping the crankcase topped off completely, and they invariably check the dipstick just after shutting down the engine. Checking the oil this way results in an erroneous reading because a quantity of oil (usually about half a litre) is still confined in the oilways and passages (galleries) of the engine, and takes some time to drain back into the crankcase. (On the image, the blue areas are where oil is likely to still be running back down to the sump). On seeing what appears to be an abnormally low level on the dipstick, these people then add more oil to the oil filler at the top of the engine. The oilways and passages all empty, and suddenly the engine becomes over-filled with oil, going way above the 'MAX' mark on the dipstick.

What happens when an engine is overfilled with oil?

So the engine was topped up when it was warm, after getting a faulty dipstick reading, or it had too much oil put in during an oil change. What's the worst that could happen? The problem with this is that the next time the engine is run, the windage in the crankcase and other pressures generated by the oil pump, etc. place a great strain on the seal on the rear main bearing.

Eventually, often much sooner than the ordinary man in the street might expect, the rear main bearing seal ruptures, and the engine becomes a 'leaker'. With a manual gearbox, this means one thing: this oil goes right onto the flywheel and the face of the clutch disc. A lubricated clutch is A Bad Thing. If this still goes unnoticed, the front seal is the next to go, and the engine then becomes a 'gusher' (or to be more colourful, it starts pissing oil all over the place). As well as smothering the clutch with oil from the rear, the oil now coming from the front leak will be neatly distributed about the engine bay as it hits the front pulley - often propelling it out as far as the brake discs. At the same time as this Hollywood disaster movie is unfolding outside the engine, things aren't working out any better on the inside. As indicated in the diagram, the correct oil level is really close to the rotating crank. Overfilling will mean the crank dips into the oil and churns it into a froth. Froth is good on certain types of coffee but not good in an engine. The mixture of aerated oil will be forced into the bearings and in case it wasn't obvious, air is not a lubricant. Typically this means that bearing damage will follow quite rapidly, especially if when driving on a motorway or at high speed. Drivers will know bearing damage when they get it. The engine smells like a garage mechanic cooking over an open flame and the noise coming from the engine is the sort of thing normally heard in vaudeville plays when a piano is pushed down a flight of stairs. As if that all wasn't bad enough, the excess oil gets thrown up into the piston bores where the piston rings have a hard time coping with the excess oil and pressure. It gets into the combustion chamber and some of it will get out into the exhaust system unburned resulting in a nice patina of oil all over the platinum surfaces of the catalytic converter. This renders it utterly useless for good.

Well, you did ask...

So what's the best way to check the oil level?

If the engine is cold (for example it has been parked overnight) the oil level can be checked right away. The oil will have had time to settle back into the sump. Just make sure the car is level. If the engine is warm or hot (after driving) then it is wise to wait for 30 minutes or so to let as much oil as possible drain back into the sump. Checking it first thing the next morning is ideal.

It's worth pointing out that you should double-check your owner's manual too - some cars, like I the '92 Porcshe Carrera, require that the oil is checked while the engine is running and the oil is at temperature.

Like the site? The page you're reading is free, but if you like what you see and feel you've learned something, a small donation to help pay down my car loan would be appreciated. Thank you.

Wet sumps vs. dry sumps.

Almost all passenger cars, trucks and SUVs use what is called a wet sump system. Looking at the diagram above, the sump (or oil pan) is the lowest part of the engine. In a wet sump system, excess oil drains back into the sump when it has passed through the engine, and the oil pump then sucks it out of the sump and pumps it back to the top of the engine. The advantage of a wet sump is that it's cost effective to build and maintain and it makes oil-checking easy for the average driver. The disadvantage is that cornering and braking can cause the oil to slosh around in the sump. This can cause the oil to not cover the oil pump pickup tube, which could starve the top end of oil, or it could get deep enough in a severe cornering maneuver to bog-down the crank, which is A Bad Thing. To counter these problems, a lot of wet sumps have baffles in them to stop the oil moving around so much, and for the average road-going consumer-level vehicle, this is a fine compromise.

Dry sumps

When it comes to racing vehicles, wet sumps simply have too many disadvantages. Instead, race engines typically use a dry sump. As its name implies, the sump of the engine is dry - it never fills with oil. In a wet-sump system, the sump has to be large enough to accommodate all the oil from the engine when it is turned off. In a dry sump system, that requirement is gone so the sump can be much much smaller. (In the image on the right, the right-most sump is representative of a dry sump). A smaller sump means the engine can be mounted lower down in the vehicle, which in turn lowers the centre of gravity - great for racing. So how can this be? A dry sump system uses a remote oil reservoir or tank, and either a second oil pump, or a single multi-stage pump. In a double pump system, one oil pump works just like a wet sump - it distributes oil to the top end of the engine, but it pulls the oil from the reservoir instead of the sump. The second pump scavenges the oil from the sump and returns it to the reservoir. In a single pump system, one pump is either a three- or four-stage pump. It has multiple circuits running off the same pump to pressurise the engine and scavenge oil back from the sump. The pumps typically don't run off the crank-driven belts so no engine power is sapped in driving them. The remote tank or reservoir can be pretty much any size and be mounted anywhere in the vehicle (usually low down again for centre of gravity reasons). There isn't oil sloshing around in the sump so there's no risk of bogging down the crank. For all these reasons, dry sumps are considered to be safer and far more dependable than their wet counterparts. So if it's that much better, why isn't this system found in consumer vehicles? Simple - increased weight, complexity and cost of having larger or more pumps and a remote reservoir with all the additional high pressure oil lines involved. For a racing team, this isn't an issue, but for Toyota or Ford, adding that sort of cost and complexity to their passenger vehicles is just a no-go.

Can car engine oil be used in a motorbike then?

No it can't. Or at least we wouldn't recommend it....

The real answer to this question lies in the type of motorbike. If the bike has with a wet clutch (ie. where the clutch sits partially submerged in the sump oil) and the engine is filled with car oil, all sorts of nasty things happen. Oils formulated for car engines have friction modifiers in them. When the engine oil gets into the clutch, the friction modifiers get to work and the clutch will slip rather than bite. Which isn't ideal. In addition, the chemical makeup of some car oils has been known to soften the clutch material on motorbikes to the point where the entire clutch pack fails. Bike oils generally don't have friction modifiers, so they don't have this problem. Check for a JASO MA spec on the bottle to be sure. If that is on the label, then it means the oil has been tested and confirmed to work with a wet clutch. Mobil have cautionary information on exactly this subject on their Motorcycle Oils FAQ page.

The other side of this coin is for bikes with a dry clutch bike, like some BMWs. In this case, the clutch is configured similar to a car in that it's never in contact with the engine oil, and if that's the case, then regular car engine oil might provide all the protection and lubrication needed for the bike. The issue then becomes a question of the exact formulation of the oil. The additive packages for car engine oil are typically balanced differently than those for motorbikes with fuel economy and emission system protection being the higher priorities. A typical passenger car engine doesn't rev to 12,000 rpm either so stuffing normal car engine oil in a motorbike engine that can run to double or even triple the rpm of a car engine could cause all sorts of problems.

The debate about whether any of this is true is burning in many forums across the internet. One site in particular casts some doubt on the issue, claiming the only difference between car and bike oil is the price. We don't subscribe to that theory but here's a link for information-seekers: Testing motorcycle oil.

Sulfated ash

There's a second good reason car oil should not be used in a motorbike - sulfated ash. It's common in many American & Canadian modern oils; without burnt oil discoloring it, it normally has a light-gray to pale-tan colouration which may become visible if a bit of the oil debris is sheared. When coloured by oil, it looks like the dreaded sludge. Unfortunately, the API SH-SN ratings are not strict enough on sulfated ash content. It's an issue that's fairly well known in some motorcycling circles, and the Japanese motorcycle industry recognized the issue very early on, creating a new oil specification specific to their needs (one, that among other things, caps the sulfated ash content very low): JASO-MA, recently revised further into to JASO-MA1 & JASO-MA2. For motorcyclists, the sulfated ash content poses a secondary issue: it means higher quantities of sulfuric acid if water gets introduced into the oil (such as from condensation within the galley spaces); since most motorcycle engines share the oil with both the engine and the transmission, the sulfuric acid is particularly problematic as the metals used in the transmission selector forks are made of cheaper steels that don't stand up to the acid nearly as well as most engine components.

Can diesel engine oil be used in petrol engines?

This is an awkward question to answer. Diesel engines run much higher compression ratios than petrol engines and they run a lot hotter, so the oil is formulated to deal with this. Plus they produce a lot more dirt in terms of combustion by-products. Diesel-rated oils typically have more detergents in them to deal with this (see Using Diesel oil for flushing above). It's not unheard of for diesel oils to clean a petrol engine so well that it loses compression. Diesel-rated oils also have an anti-foaming agent in them which is unique to diesel engines, and not needed in petrol engines.

So is that the be-all and end-all answer? Well not really and that's why this is a difficult question to give a straight answer to. The above statement is more relevant to commercial diesel engines. Nowadays, just about all passenger car / light commercial oils (including OEM ones designed for both petrol and diesel engines) will carry the ACEA A and B specifications. ie. formulated to satisfy the requirements for both types of engine. So just because the oil is labelled "Diesel" doesn't mean it's not suitable for petrol engines - it will more than likely carry an ACEA A3 / OEM petrol spec as well.

However care must be taken that the right diesel spec is being chosen - modern common rail / direct injection diesels typically require at least an ACEA B4 spec to cope with the higher piston temperatures that can cause piston deposits (and stuck rings). ACEA B4 is fine where B3 is recommended.

Of course following the VW Dieselgate fiasco in 2015, this could all be a moot point if light duty diesel engines disappear from our cars.

And so to engine additives

An engine is designed to be lubricated by oil, formulated by big petro companies and full of additives that perform anti-wear, heat transfer, lubrication and detergent functions. That doesn't stop dozens of companies formulating extra additives and selling them as pour-in-the-engine and pour-in-the-tank solutions for problems an engine may or may not have. In the bad old days, these were known as snake oil - back when putting Teflon® in an engine seemed like a good idea. (Here's a famous old snakeoil article.)

In our opinion (and that doesn't mean we're right) a large number of additives are placebos to put minds at rest. It's not common to find properly independent lab analysis of the products that will support their claims.

There is a page dedicated to this topic that covers, primarily, the endless lawsuits for false advertising against many manufacturers. Does this mean the product didn't work at all, or it didn't work as the advertising had promised? Hard to tell but head over to my additives page for more information.

Nanolubricants

Not something off Star Trek, although it sounds like it. Nanolubricants use the geometrical properties of miniature particles to provide lubrication. A couple of companies are working on these new generation lubricants; New York-based Applied Nanomaterials (ApNano) is one of them. Their R&D lab in the commercial arm of the Weizmann Institute of Science in Israel is initially developing an onion-type nanostructure, i.e. a multilayered hollow structure of nested spheres called NanoLubTM. According to the theory of the company's founders, such a structure can replace lubricants, because it works like a box moving along a near infinite layer of super-miniaturized ball bearings. They claim that respected institutes worldwide have proved that powder made from these nanostructures is six to ten times more effective than regular lubricants.

In their case, the nanospheres are built from tungsten disulfide (WS2). The layers slide past each other, reducing friction, while the hollow cores provide flexibility. Applied Nanomaterials claims the materials can withstand immense pressures. The material acts as a kind of solid ball bearing between the metal layers, rather like the wheels of a tank tread. In addition, the nanostructures insert themselves within each metal layer, while other nanostructures slide over them, creating a smooth layer at the molecular level.

The idea is that unlike oil, the nanolubricant never wears down; it is permanent and requires no maintenance. Theoretically, a nanolubricant can be used for various friction reducing applications, such as on the outer coating of ships and planes to reduce water and air friction, respectively. Think of what it could do to the sex toy industry....

The powder will eventually stand on its own as a lubricant, however Applied Nanomaterials realizes that recognition of the technology requires collaboration with lubricant manufacturers as an additive to existing lubricants. The problem of course is that if this lubricant never needs changing, anyone who decides to mass manufacture and market it is going to lose a chunk of revenue - once a Nanolubricant is put into an engine, the customer never needs to buy any more. Great for the customer, bad business model for the company who dares to market it.

Applied Nanomaterials competitors are developing similar materials, but based on nested carbon nanotube structures that over time tend to disintegrate under friction from the materials they lubricate.

Don't expect to see NanoLubTM on the shelves in large quantities just yet though. It can take a day to manufacture just 750g of the stuff. At the time of writing, it was being marketed by SONOL Israel Fuel Company

Another player in this brave new world of Things That Are Altogether Too Clever™ is Nanovit, based in the UK.

For the chemists who are reading this, NanoVit builds a nano-scale colloid system at the metal surface and this dynamically changes as the frictional forces are applied to the surface. According to Nanovit, this stuff is based on a structure formed using specific nano-particles of Aluminium Oxide, Silicon Dioxide and Carbon. It does not use carbon nano-tubes and is rated as completely harmless in toxicology testing. It is a permanent coating, existing between many oil changes. The colloid system dynamically "swells" and contracts according to the force and space, causing the resetting of surface geometry to the optimum during the working process of a friction surface, additionally the new surface changes the properties of the thin oil-film layer, interacting with it to improve properties (viscosity index andother key indicators) and protect the molecular structure to prolong oil life. The adherence of the coat to the metal is a bonding process that rebuilds scuffed surfaces and displaces all contaminants (also preventing their re-build up).

For the non-chemists reading this, it's essentially a self-repairing surface right out of science fiction that sticks to the cylinder walls in the engine. Or would that be science friction? Yes, yes, horrible pun. Lets move on.

An alternative to engine additives: pre-pressurisation

![[auto engine lube kit]](images/autoenginelube.jpg) What the additive manufacturers say is true - when an engine is started, there really is very little oil in the right place - most of it is in the sump. AutoEngineLube.com seem to be offering an interesting alternative. They have a system which uses a cylinder of pressurised oil and a solenoid valve, all connected to the regular oil system.

It works with only one moving part, (the solenoid valve - duh!). When the key is turned on it opens the valve and the oil that was trapped in the tank the previous time it was running goes back into the oil gallery in 1 or 2 seconds and the low oil pressure light will flash off. There's likely to still be a little lag before full-on lubrication gets to the main bearings, but it looks like, this system will massively reduce that lag compared to starting from cold - it pressurises the system before the starter engages. Of course an engine that has set up for a few months and is completely dry will take a few more seconds. When the engine is turned off the solenoid valve shuts off in 30 milliseconds so that the pressure on the tank equals the pressure the last time it was running. The tank will hold more than enough oil to accomplish this. Its completely over engineered as the tank is rated for over a thousand pounds and the hose is good for 300lb. Because the valve is designed for an industrial application with an expected duty life of several million cycles, AutoEngineLube give it a lifetime warranty. It only uses previously filtered oil from the gallery so no damage can be done by it in any way.

What the additive manufacturers say is true - when an engine is started, there really is very little oil in the right place - most of it is in the sump. AutoEngineLube.com seem to be offering an interesting alternative. They have a system which uses a cylinder of pressurised oil and a solenoid valve, all connected to the regular oil system.

It works with only one moving part, (the solenoid valve - duh!). When the key is turned on it opens the valve and the oil that was trapped in the tank the previous time it was running goes back into the oil gallery in 1 or 2 seconds and the low oil pressure light will flash off. There's likely to still be a little lag before full-on lubrication gets to the main bearings, but it looks like, this system will massively reduce that lag compared to starting from cold - it pressurises the system before the starter engages. Of course an engine that has set up for a few months and is completely dry will take a few more seconds. When the engine is turned off the solenoid valve shuts off in 30 milliseconds so that the pressure on the tank equals the pressure the last time it was running. The tank will hold more than enough oil to accomplish this. Its completely over engineered as the tank is rated for over a thousand pounds and the hose is good for 300lb. Because the valve is designed for an industrial application with an expected duty life of several million cycles, AutoEngineLube give it a lifetime warranty. It only uses previously filtered oil from the gallery so no damage can be done by it in any way.

Their system comes as a kit and requires some menial installation - most savvy home mechanics should be able to do it. I'm not sure how it would affect the warranty on a car engine. In theory, if it works, it ought to make no difference but you know what manufacturers are like - sneeze on an engine and it's likely to void the warranty.

Pop over and check them out if you're interested. If you end up buying one of these, we'd like to know what sort of results you get so we can add an objective review to the site. AutoEngineLube.com Another site sells a similar product - PreLuber.com.

It's worth pointing out that pre-lubers have been around for quite a while; the original systems featured an electric pump that circulated the oil from the sump before the starter turned. The pump would bring the oil up to full operating pressure before an engine start was attempted. A reader of this site e-mailed us about this. He had one on an old MG-TD, because the car got very infrequent use; it worked rather well and he never had any major engine problems with it installed. Enginelube.com still do the "old style" pre-lubers but their website has vanished so we don't have a good link for them now.

Case study: MOROSO Accumulater (pistonless upright bottle type) pre-oiler on V8 Zephyrs

A reader contacted me about using pre-oilers on classic vehicles. Here's what he had to say:

"I use the MOROSO Accumulater 2 which is a pistonless upright bottle type. I researched these after experiencing oil pressure drops of 20psi on uphill right hand corners at speed. The Moroso 2 cured it right away. I plumbed it directly into where the oil sender went and used a tee for the oil light sender. I have a ½" ball valve at the bottle I use but intend to rig a choke cable to use it from inside the car. Electric solenoid valves are available too. To do an oil change the factory fitted tire valve is pumped with 20psi of air and the tap opened, old oil is then fully pushed out into the sump via the oil feeds. The car if used for racing etc is driven with the ball valve open, any drop in oil pressure is taken over by the accumulater until the oil pump pick up is covered again. I also use the oiler to lube the engine (Ford V8) by turning the valve with the engine off, the oil pressure goes up to about 20-30psi (you can hear it gurgle in the rocker covers!). After 10-15 seconds I then start the engine. You turn the valve off with the engine running to trap oil for the next start up.Racers run these on engines that can be "claimed" after a race as if the engine had a high doller sump pan they would lose it with the engine. The Accumulater works better than any trap door or baffled sump if you spin backwards off a track too!"

There are further writeups of this particular installation available at StockCarRacing.com.

Picture credit: MkIII Zephyr V8s

Oil filters and filtration.

Thanks to one reader who noted that in all of this page, until mid-2001 I had not given much, if any space, to the topic of filters and filtration. So here we go.

It's all very well changing the oil often, but it's not just the oil that helps prevent engine wear. The oil filter does its part too. Dirt is the prime cause of engine wear. Not big dirt, as found in a yard, but minute particles of dirt. It's dirt nevertheless, and it's abrasive. These contaminants vary from road dust (which are razor-like flakes from an engine's perspective) that doesn't get filtered out by the air filter, up to actual metal particles - the byproducts of the casting swarf from the original engine manufacture, and basic engine wear. All this nastiness is carried around by the oil into the minute parts of the engine, being rammed into the precision clearances between bearings and other moving parts. Once in, they don't come out easy, but tend to stay there, wearing grooves, grinding and generally messing up the engine. Other debris that causes problems are a by-product of the mere way an engine works - sooty particles from the combustion process can be forced past the piston rings and transported around in the oil too. This is definitely A Bad Thing - the soot acts like a sponge and soaks up other oil additives reducing the oil's anti-wear properties, and messing up it's viscosity. All this dirt is why oil goes black when it's used. That lovely syrup-like yellow when first put in the engine is pure oil. The black stuff that comes out at an oil change is that same oil full of contaminants and by-products from wear and tear.

That's where the oil filter comes in. It's job is to catch all this crap floating around in the oil, and to stop it from recirculating. Most consumer oil filters are the spin-on type. They're shaped like an aluminium can and spin on to a threaded oil feeder poking out of the side of the engine somewhere. They're called 'full-flow' oil filters because they sit in the normal flow of the oil through the engine. Sort of like an electrical component in series with all the other electrical component. Because it sits in-line, it has to be designed not to restrict the flow of oil around the circuit, and thus can only really be effective at stopping the larger particles. Large, in this case, is around the 20micron size. So here's the catch. The smallest contaminants are in the 10-20micron size range. Not only is that "extremely small", but it means that they pass right through the oil filter and back out into circulation. This is why regular oil changes are a necessity, because these tiny little things can be the most damaging.

There is another alternative, but it's only really used in heavy applications or for racing. That alternative is to fit a secondary bypass oil filter. This is sort of like a filter in parallel with the primary one. It doesn't restrict the flow of oil in the main circuit, but the oil that passes through it is filtered down to the 5 micron range, thus removing even the smallest contaminants. The newest filters claim to work down to 1 micron, though I can't confirm nor deny those claims. The upside is that by cleaning the oil so completely, bypass oil filters increase not only engine life, but also the life of the oil itself. This means longer service intervals.

Magnetised oil traps

In the early 2000's, magnetic filter additions started to appear on the market. We were sent one in 2001 to try out and it really did seem to work. The product in question was called the Bear Trap BT500. Their website can be found here (now owned by One Eye Industries). It's basically a sleeve made of foam rubber and plastic with some magnets in it. It bends to clamp around the outside of a regular spin-on oil filter. The idea is that the magnets will attract any metal debris in the oil and stick them to the inside of the oil filter wall, thus preventing them from going back into the oil circulation. Being of a curious nature (or stupid, depending on how you look at it) we decided to dismantle my oil filter after using the Bear Trap for 5000 miles. We learned a couple of things.

- You shouldn't try to do this yourself.

- It's bloody messy.

- But most importantly, after a brief period in accident and emergency to stitch up the gash in my hand, I discovered that sure enough, there were tiny arrangements of metal filings clustered around the inside of the oil filter wall where the magnets from the beartrap had been. You'll excuse the lack of photos to prove the point, but I had other things to worry about. If you visit their website or that of FilterMag (below) you'll see similar cutaway photos.

So can we recommend their product? Yes.

Another alternative to the Bear Trap is the FilterMag - essentially the same style of product but from a different manufacturer.

An alternative to custom magnetised oil traps.

Thanks to John Nightingale who read these pages and then felt he should contribute something. For readers who do more than just change their oil filters - ie. taking off the oil pan completely, John writes:

"

Next time you are in the mall or high street, drop into the Radio Shack or a hardware store and purchase a package of modern, powerful ceramic magnets. These are available in various shapes and they are cheap. Radio Shack sells a package of two wafer shaped magnets, for instance. Stroll out to your car at the end of your shopping trip, bend down and stick these magnets onto convenient flat surfaces the bottom of your oil pan either side of the drain hole or as convenient. Now the magnets will magnetize the steel of the oil pan in their area. On the inside, particles coming through the field established by a magnet will be sequestered by being stuck to the bottom of the oil pan. Next time you take off the oil pan, clean it out in the usual way, pull off the magnets from the outside, clean them up and then stick them onto the inside of the oil pan at the bottom but clear of the drain hole. This will give an even better result since now the oil is exposed to the naked magnets themselves. The bottom of the oil pan in the area of each of the magnets is also magnetized, of course, and contributing to the effect. Resist the temptation to stand the magnets on edge to expose more of their surface to the oil. Placing the magnets flat on the oil pan uses the oil pan's steel as a keeper for the magnets and will ensure that they stay powerful. Placing the magnets flat will increase the area of the oil pan that is part of the magnetic circuit so you will loose no particle pick up area by having the magnets lying flat.

"

Magnetised oil traps - doing it yourself.

There's nothing really special about magnetised oil traps other than the type of magnet they use. Bear Trap and FilterMag basically offer a consumer-oriented product. But if you're a tinkerer, there's nothing to stop you doing it yourself. The magnets normally used are Neodymium, nearly the most powerful nonelectric magnet type. They are the kind of magnet used in computer hard drives, often coming in pairs held just a few millimeters apart with the back end of the hard drive head assembly (the part being made of coiled wire) in between. If you can find a couple of old hard drives - try the local computer junk store - you ought to be able to disassemble them and take the magnets out to stick to your own oil filter. John Nicholas Sarris, a reader of my site, suggested this and provided the following photos as an example.

|

|

||

|

|

||

|

|||

The importance of neodymium magnets

We thought it worth pointing out here what a potential disaster awaits the home tinkerer who just grabs any old magnet and sticks it on the outside of their oil filter. The common or garden ferrous magnet, like those horrible souvenir magnets stuck to your fridge (you know you've got some) are usually made from iron, and thus have a limited life span which in some cases can be as short as 6 or 12 months. During this time they progressively lose thier power. Not enough for that hideous magnetic photo frame to drop off the fridge, but enough to be a problem if it was stuck to an oil filter. Why's that then? Well, come the end of the filters life, just as the magnet is weakening and the collection of metal particles is at it's highest, one good jolt and it could dislodge, and a large collection of metal shavings and filings could detach from the inside of the filter and find its way back into the engine all in one go. That would be bad. So as appealing as it might be to have the magnetic photo of the relative you don't like (next to the giraffe from Whipsnade zoo) be stuck in a filthy oily place on a car, don't do it.

Larger filters on standard cars?

There's a school of thought that says enlarging the oil filter on a car is A Good Thing. Why is this?

The small oil filters fitted to engines these days tend to have their bypass valves set to open at quite low pressures (8-11psi or so). This valve is a safety device designed to bypass the oil filter element (the actual paper or fabric filter inside the canister) in the event of a high pressure differential - typically from poor maintenance - ie. a blocked filter element. Once the pressure differential between the two sides of the filter element is too large, the bypass valve pops open and the unfiltered oil bypasses the filter element completely and just runs back out into the engine.

But the bypass valve can open under other circumstances too. For example, thick, cold oil doesn't pass through the filter element very well, resulting in a high pressure differential, meaning the bypass valve opens.

The same can happen in warm engine if the driver has a lead foot. A quick acceleration away from the traffic lights can result in the oil pressure in the engine increasing quickly - quicker than the filter element can handle - and for a few moments while the pressure equalises inside the filter, the bypass valve will again be open.

So how does this pertain to larger filters? Larger filters have bigger filter elements, which means they tend to have higher pressure bypass valves (around 14-18psi) meaning there needs to be a much bigger pressure differential before the oil will bypass the filter. Better for cold starts, short commutes and those with a love of acceleration.

There are some things to be aware of if this approach is to be attempted, all of which are relevant, and none of which we can confirm or deny:

- Bigger filter = more "dead" space = more oil. Remember to add more oil to the engine to keep the oil level at the correct mark on the dipstick. This isn't necessarily a bad thing - more oil doing the same job theoretically means less stress on the oil.

- Oil may take a little longer to circulate around the engine after startup, as the pump may have to fill up the larger capacity oil filter. Note that the oil filter backflow preventer (anti-drainback valve) doesn't help here because it does eventually allow the oil to drain out of the filter with the engine switched off. Anti-drainback refers to the function of keeping the unfiltered oil from draining back into the engine - it eventually passes through the filter and drains out the normal way.

- Availability of filters and fouling. Putting a larger filter on might foul something else in the engine bay. That is if a larger filter can be located to start with. The rule of thumb is to go to a motor factors shop, and find the oil filter that was originally designed for the engine. Then look through the myriad of larger oil filter boxes for a bigger filter that has the same screw thread and sealing ring diameter. Nowadays most spin-on filters have a 20mm screw thread so that's not going to be the hard part. Finding the same sealing ring diameter is the thing to be careful of. And don't ask the people at the parts counter. Because of liability issues, they're unlikely to sell anything other than exact filter for the make and model of vehicle.

Like the site? The page you're reading is free, but if you like what you see and feel you've learned something, a small donation to help pay down my car loan would be appreciated. Thank you.

A Practical example of the proper procedures saving an engine.

I (the author) started these pages back in 1994 and have been adding to them ever since. I've always followed my own advice and in 2005, it paid off big time. I'll tell this in the past tense because it'll get lost in the page and I'll forget to update it when I change motorbikes.

So I owned a 2001 BMW R1150GS motorbike. I bought it pre-owned from my local dealer who assured me it had been through the workshops as part of the "standard procedure" of them taking a bike in and re-selling it. For 2 years I'd been riding it with horrible engine noise and engine detonation (pre-ignition). Every time I took it back to the dealer, they were adamant there was nothing wrong with the engine, and that "they all do that". Not believing them, I finally found an independent BMW specialist who took the engine apart for me. It turned out the BMW dealership had lied - the bike had never been in their service department. This was evidenced by the fact that the cylinders had sand in them. The dealership had never bothered to check the bike and wouldn't believe my complaints about the noisy engine. The independent mechanic fixed it all up for me - an $1100 repair bill that involved basically stripping down the entire engine, honing the cylinder barrels, putting in new piston rings, cleaning the pistons, barrels, heads, throttle and airbox, flushing and cleaning the whole thing and putting it all back together. The point is that during the two years I'd been riding it with sand in the engine, I'd been religiously topping up the oil and changing the filter. It's a testament to BMW engineering that the engine ran without seizing up, but it's also a testament to paying attention to your oil changes. If I'd let it slide, or not done the filter, that engine would not have been a rebuild - it would have been a far more costly brand new engine.

How to perform an oil change

A good number of readers will get to this point in the page and think "this is easy - I could do this!", and for the most part, you can. In our DIY articles, there is a page on how to change your engine oil. Enjoy.

Using oil extractors

There's another way of getting the oil out of a car's engine during an oil change - oil extractors. The typical extractor uses a vacuum mechanism either generated by pumping a handle to build up a vacuum in the reservoir, or by a powered vacuum pump. The example on the right is a manual style. Basically the handle is pumped to build up a vacuum, then the extractor hose is poked the oil and let her rip.

Extractors are a convenience item designed to eliminate the need to get the vehicle up on a ramp, or for someone to crawl under it and deal with the drain plug. The only problem with an extractor is that there's never a 100% guaranteed that all the oil is drained out. For it to work best, the suction hose needs to be in the lowest point of the sump pan, where the drain bolt is. The problem is that first of all, the sump isn't transparent, so it is difficult to tell exactly where the tip of the suction hose really is. (Remember that it is being fed in through the dipstick tube). Secondly, a lot of sumps have anti-slosh baffles in them both horizontally and vertically. If the extractor pipe isn't properly threaded through one of the baffle holes, it's possible to leave the entire sump's-worth of oil in there. Third, and finally, any congealed oil, clogs or clumps of sludge will likely get stuck in the extractor hose causing a blockage. That would mean taking the hose out, cleaning out the blockage, then feeding it back in again which exposes the risk of the initial two problems all over again.

Oil extractors are more commonly used for getting oil out of smaller engines like lawnmowers. I've never used one in a car engine but because of the problems mentioned above, I can't imagine it would be especially efficient. Having said that, the Smart car has no sump drain so the only way to get oil out of those things in a service is to use an extractor.

Footnote: many sump drain bolts on cars are actually on the side of the sump, not the bottom. So even if you drain the oil using the sump bolt, there's still going to be a little dead space below the level of the bolt. An oil extractor would help clean this area out - so maybe the best option is to drain the oil using the drain hole and then fish around with an oil extractor afterwards.

Finally, and just as importantly: Disposing of used engine oil.

![[oilcare]](images/oilcare.gif)

Think about it for a minute. What did you do with that last oil change? Pour it away down a drain? Seal it and bin it? The annual average for oil which is just washed away is 720Million gallons! About 120Million of that is from tanker spills which leaves another 600Million from domestic and business disposal. This all ends up polluting the groundwater.

So what can you do? Well, you can dispose of your used oil properly. Firstly, it's worth noting that engine oils which have been used are mildly carcinogenic. This means cancer, specifically skin cancer. To be safe, wash any off quickly with a de-greaser like GUNK. For heavens sake, don't use petrol (gasoline) - most fuels contain long chain hydrocarbons, which when exposed to skin pass right through to the blood stream. (This can mean liver damage, and possibly failure) Better still, wear protective gloves. Once the oil is drained into a suitable container, try your local garage. All garage workshops must have disposal barrels and many will allow you to dump your oil into their barrels. In the UK, many DIY superstores now have oil disposal banks where you can empty your used oil, and it's collected every couple of days by a tanker. So next time, just think about first. If only for the fact that in most civilised countries, it's actually an arrestable offence to dispose of oil in the public sewerage system. If you live in the UK, phone 0800 663366 to find the location of your nearest oil bank. Alternatively, you can use the postcode search on the oilbank website.