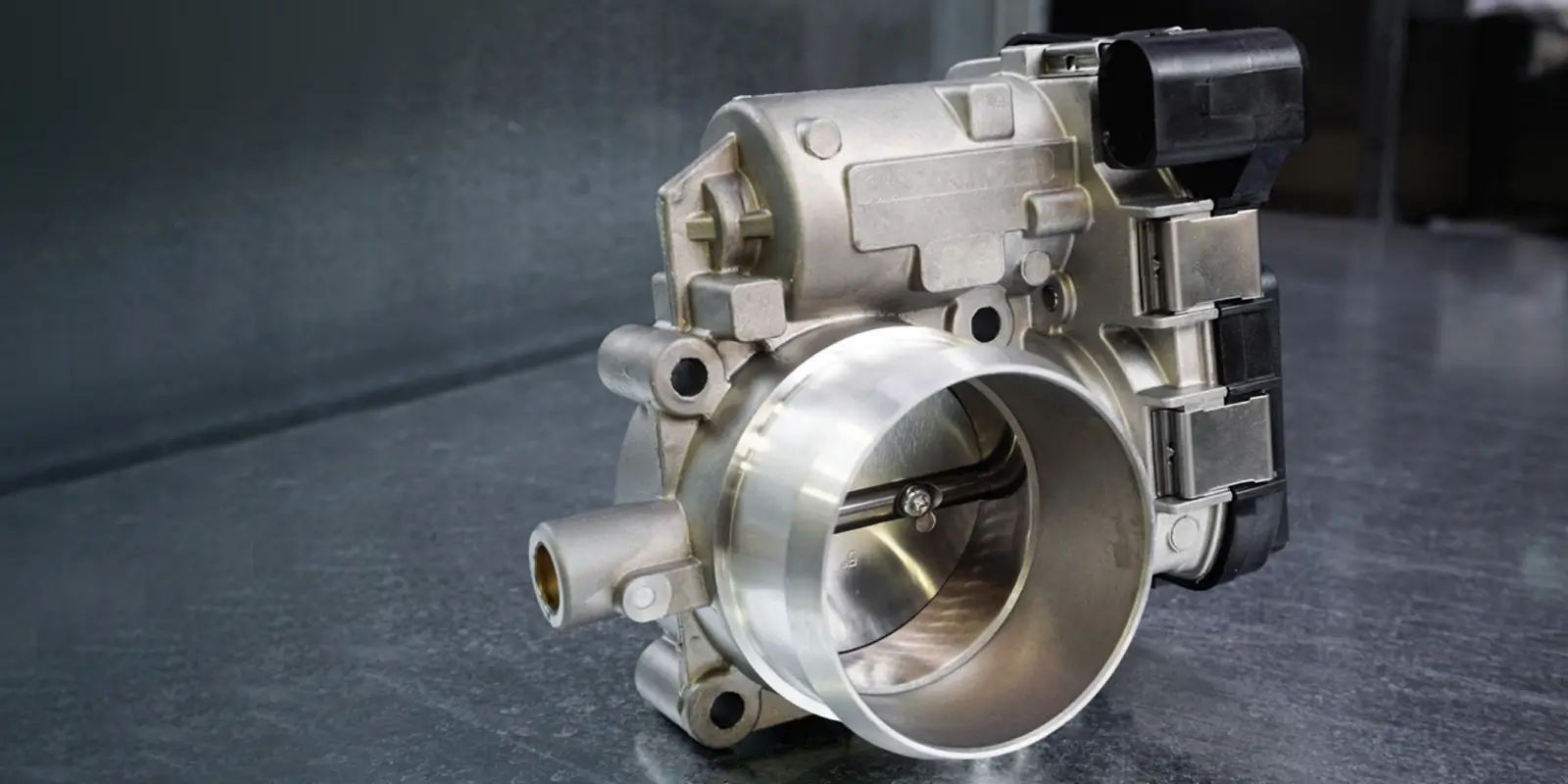

The throttle position sensor (TPS) is a critical component in modern vehicle engines, playing a pivotal role in the engine management system. Its primary function is to monitor the position of the throttle plate in relation to the driver’s input via the accelerator pedal. This information is relayed to the engine control unit (ECU), which adjusts fuel injection and ignition timing accordingly. When the TPS malfunctions, it can lead to a range of performance issues that can affect drivability and fuel efficiency.

In my experience, TPS failures are often subtle at first. Drivers may notice a delay in acceleration or a slight hesitation when pressing the gas pedal. These initial symptoms can be misleading, as they might be attributed to other issues such as fuel delivery problems or even transmission slip. However, as the TPS continues to degrade, the symptoms can escalate into more pronounced issues, including stalling, erratic engine behavior, or even a complete loss of power.

One of the most common scenarios I have encountered involves a vehicle that experiences a rough idle. This can manifest as a fluctuating RPM when the vehicle is stationary, often leading to the assumption that the issue lies with the idle air control valve or the fuel injectors. While these components can indeed cause similar symptoms, the underlying culprit may very well be a failing TPS. A malfunctioning sensor can send incorrect voltage signals to the ECU, causing it to miscalculate the necessary air-fuel mixture, which can result in an unstable idle.

The conditions under which the TPS tends to fail can vary. Heat is a significant factor; sensors can become less reliable as they heat up, especially in vehicles subjected to high engine temperatures or prolonged operation in stop-and-go traffic. Additionally, the physical wear and tear from vibration and movement can contribute to sensor degradation over time. Dust and moisture intrusion can also exacerbate problems, particularly in older vehicles with less robust sealing.

Another real-world observation involves the symptoms exhibited during acceleration. A failing TPS can lead to what feels like a “flat spot” during throttle application. For instance, when merging onto a highway or overtaking another vehicle, the driver may experience a momentary lag or lack of responsiveness. This can be frustrating and dangerous, especially in situations requiring quick acceleration. In some cases, the vehicle may even enter a “limp mode,” where the ECU restricts engine performance to protect it from potential damage.

It is important to note that not all TPS failures result in severe symptoms. In some instances, the sensor may still function but provide inaccurate readings. This can lead to poor fuel economy or increased emissions. Drivers may not notice these effects immediately, but over time, they can lead to costly repairs, particularly if the vehicle fails emissions testing.

The diagnostic process for a malfunctioning TPS can be straightforward, yet it often requires careful attention to detail. A common method involves using an oscilloscope to monitor the voltage output of the sensor while the throttle is actuated. Ideally, the output should show a smooth, linear progression as the throttle plate opens and closes. Deviations from this pattern can indicate a faulty sensor. However, one must also consider potential wiring issues or connector problems that could lead to similar symptoms.

In some cases, a simple cleaning of the connector and ensuring a secure fit can resolve issues attributed to the TPS. Corrosion or dirt can impede the electrical connection, leading to erratic sensor behavior. However, if the sensor itself is damaged, replacement is usually the most effective solution.

When replacing a TPS, it is critical to ensure proper calibration after installation. Many modern vehicles require a relearning process where the ECU adapts to the new sensor’s characteristics. Failing to do so can result in continued performance issues, even with a new component.

There are also various types of TPS designs, including potentiometric and Hall-effect sensors. Each has its own failure modes and characteristics. For instance, potentiometric sensors can wear out over time due to mechanical friction, while Hall-effect sensors may fail due to electrical issues. Understanding the specific type used in a vehicle can provide insight into potential issues and lifespan.

In terms of preventive measures, regular vehicle maintenance can go a long way in ensuring the longevity of the TPS. Keeping the throttle body clean can help prevent buildup that may affect the sensor’s operation. Additionally, monitoring engine temperatures and addressing any cooling system issues can minimize stress on the sensor.

The interplay between the TPS and other engine management components cannot be overstated. A malfunctioning TPS can lead to a cascade of issues affecting fuel delivery, ignition timing, and even transmission behavior. Therefore, when diagnosing drivability issues, it is essential to consider the TPS as a potential factor, especially in cases where other components appear to be functioning normally.

In summary, the throttle position sensor is a vital element of a vehicle’s performance and efficiency. While it may not be the first component that comes to mind when diagnosing engine issues, its impact is significant. Recognizing the symptoms of a failing TPS and understanding the conditions that lead to its deterioration can help in maintaining optimal vehicle performance. As with many automotive components, a proactive approach to diagnostics and maintenance can prevent minor issues from escalating into major repairs.