Automotive engines are intricate systems where mechanical components work in harmony to convert fuel into motion. Among these components, engine belts play a vital role in ensuring that various parts operate smoothly and efficiently. A malfunctioning belt can lead to a cascade of problems, affecting everything from engine performance to accessory functionality.

There are several types of belts found in modern vehicles, each serving a specific purpose. The most common types are serpentine belts, timing belts, and accessory belts. Each belt is designed to withstand the harsh conditions of an engine bay, including high temperatures, vibrations, and mechanical loads.

Serpentine belts are perhaps the most recognizable. They are long, continuous belts that wind around multiple pulleys, driving components such as the alternator, power steering pump, and air conditioning compressor. Because they are used in multiple systems, the failure of a serpentine belt can lead to a loss of power steering and electrical output, making it critical to monitor their condition.

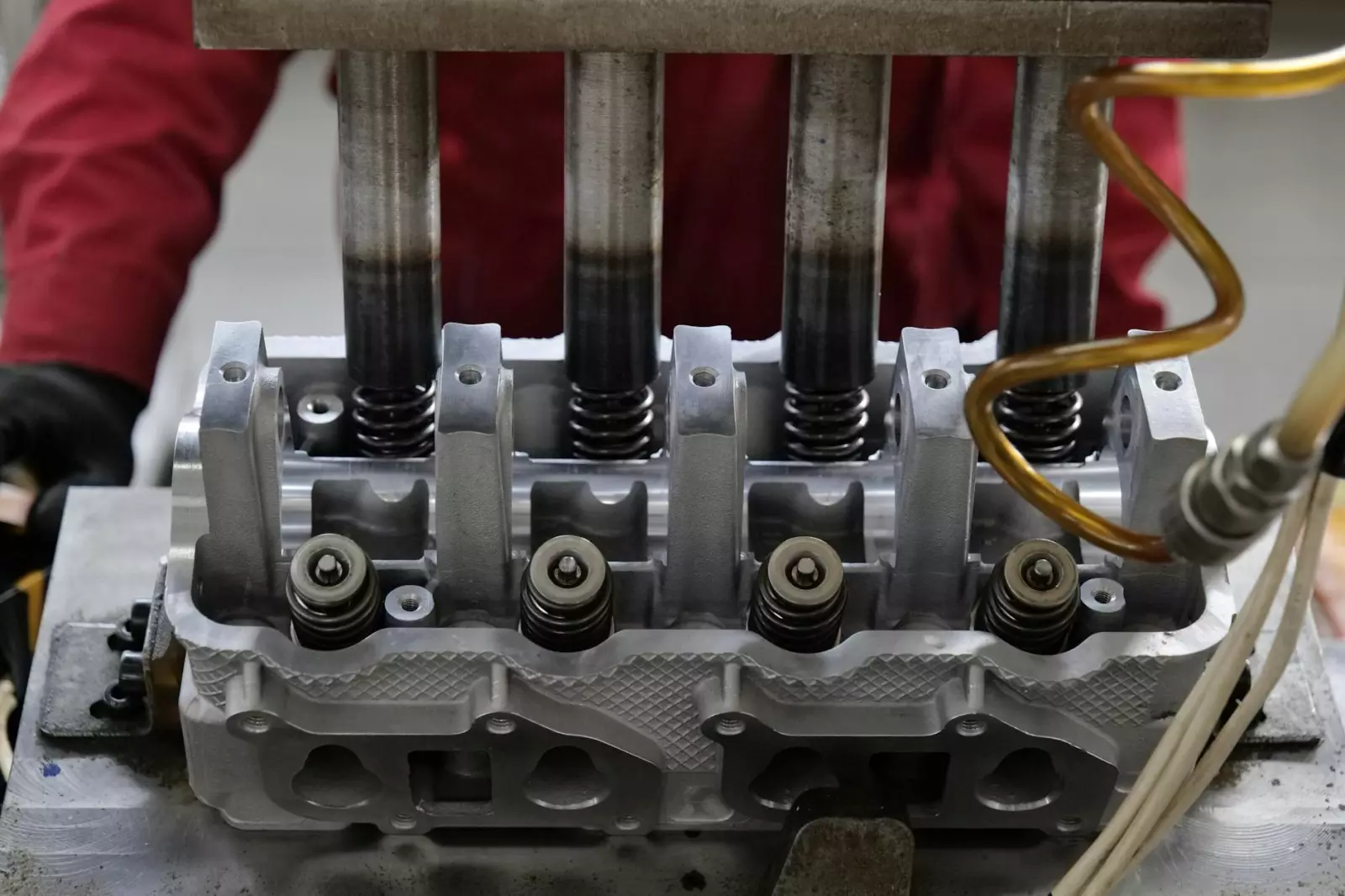

Timing belts, on the other hand, are crucial for maintaining the synchronization between the crankshaft and camshaft. This synchronization ensures that the engine's valves open and close at the correct times during the intake and exhaust strokes. Timing belts are typically made from reinforced rubber and have a specific service interval, often around 60,000 to 100,000 miles, depending on the manufacturer's recommendations. A failed timing belt can result in severe engine damage, particularly in interference engines, where the pistons can collide with open valves.

Accessory belts, which may sometimes be referred to as V-belts or fan belts, are used in older vehicles or specific applications. These belts are typically narrower than serpentine belts and are designed to drive individual accessories. While they are less common in newer vehicles, they still can be found in some models and should be inspected regularly for signs of wear.

Over time, all belts are subject to wear and tear. Common signs of belt deterioration include cracking, fraying, or glazing on the surface. Many drivers may notice a chirping or squealing noise coming from the engine bay, which often indicates that a belt is slipping or misaligned. In some cases, the noise can be harmless, merely indicating that a belt needs adjustment or replacement. However, persistent noises should prompt further investigation, as they may signal deeper issues.

Temperature plays a significant role in belt longevity. Engine compartments can reach high temperatures, particularly in stop-and-go traffic or during heavy load conditions. The rubber compounds in belts can degrade faster when exposed to excessive heat, leading to premature failure. Likewise, environmental factors such as oil leaks or coolant spills can accelerate deterioration.

Regular inspections are essential for identifying potential issues before they escalate. During routine maintenance, it is advisable to check the tension and condition of the belts. A belt that is too loose may slip, while a belt that is too tight can place undue stress on the pulleys and bearings.

In real-world scenarios, I have encountered instances where a simple belt replacement resolved multiple issues. A vehicle exhibiting electrical problems due to a failing alternator often turned out to have a worn serpentine belt. Once replaced, the vehicle regained its charging capability, illustrating the interconnected nature of these components.

Another observation I've made is how often timing belt replacements are overlooked. A vehicle may run smoothly, but without attention to the timing belt's service interval, a sudden failure can lead to catastrophic engine damage. The costs associated with such repairs far exceed the preventive maintenance of regular belt checks and replacements.

In summary, engine belts, while often overlooked, are critical components that can significantly impact vehicle performance and reliability. Understanding their roles and recognizing the signs of wear can help maintain the integrity of the engine and its accessories. Regular inspections and timely replacements are key to avoiding unexpected failures and ensuring long-term vehicle health.