The Positive Crankcase Ventilation (PCV) valve is a small yet crucial component within the engine's air management system. Its primary function is to regulate the flow of gases from the crankcase back into the intake manifold. This process helps to reduce harmful emissions and maintain optimal engine performance. In my years of hands-on experience, I have encountered numerous instances where PCV valves have malfunctioned or become clogged, leading to a range of performance issues.

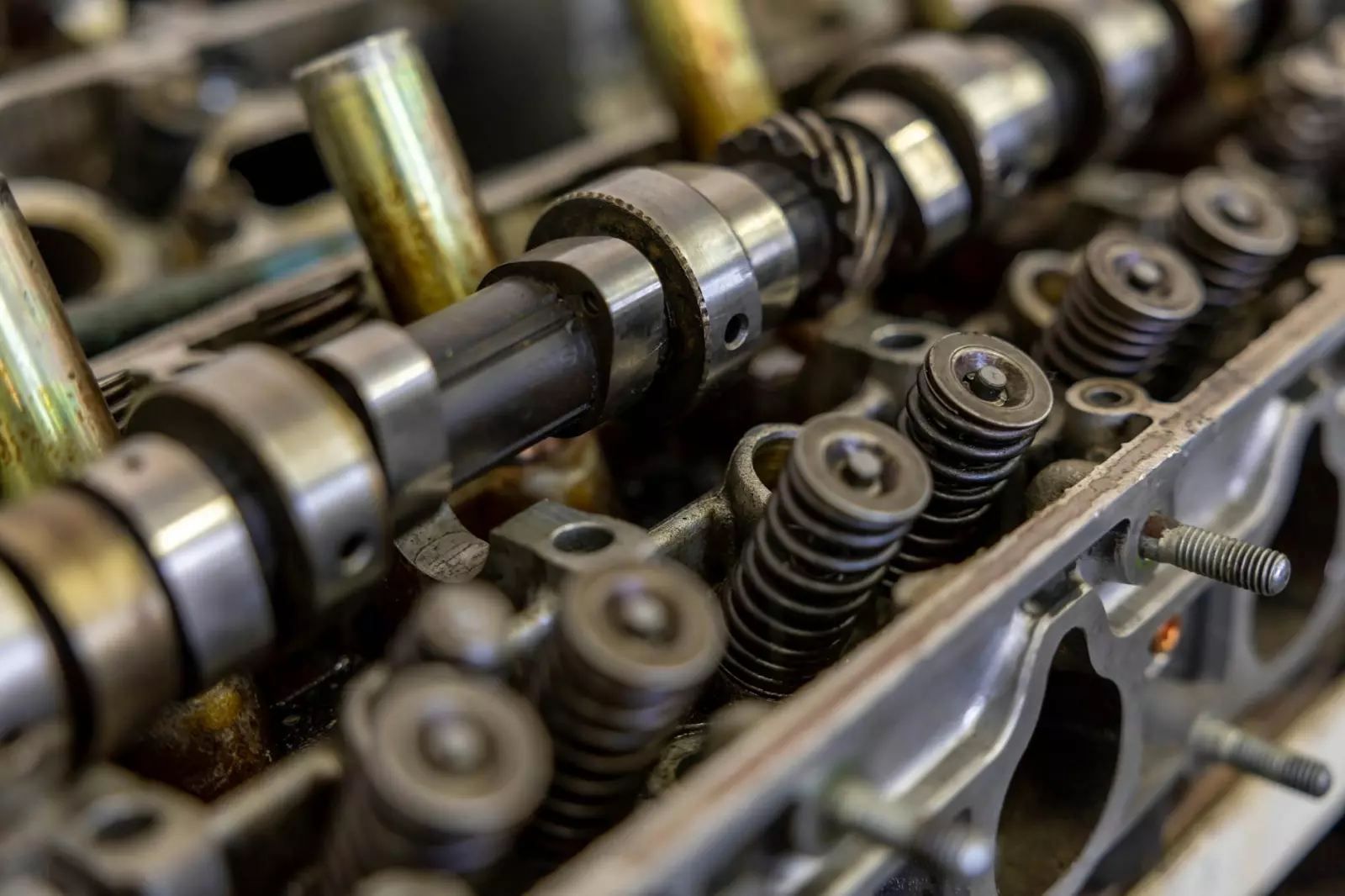

The PCV system operates by channeling blow-by gases – unburned fuel and combustion gases that escape from the combustion chamber – back into the intake. This not only helps in reducing emissions but also aids in maintaining pressure within the crankcase. When functioning correctly, the PCV valve is designed to open and close in response to engine load and speed, ensuring a balanced flow of gases. However, when the valve becomes stuck, clogged, or otherwise compromised, it can lead to a cascade of problems.

One common issue I have observed is excessive oil consumption, often mistaken for a sign of worn piston rings or valve seals. In reality, a malfunctioning PCV valve can create a vacuum that draws oil from the crankcase into the intake system. This not only increases oil consumption but can also lead to oil fouling the spark plugs. In many cases, this issue goes unnoticed until drivability problems or check engine lights become apparent.

Another symptom of a failing PCV valve is increased engine pressure. A blocked or malfunctioning valve can cause pressure to build up in the crankcase, leading to oil leaks around seals and gaskets. In severe cases, this can result in a blown rear main seal, which is a costly repair. The pressure can also cause the oil to foam, reducing its lubricating properties and potentially leading to engine damage over time.

In colder climates, I have noticed that PCV valves can become sluggish due to the accumulation of moisture and oil sludge. This can lead to a condition where the valve fails to open properly, causing increased pressure and oil leaks. In some cases, drivers may report rough idling or stalling, especially during startup. The cold temperatures can exacerbate the problem, making it critical to monitor the PCV system during winter months.

Over time, the PCV valve itself can become clogged with carbon deposits and sludge. This is often exacerbated by poor engine maintenance, such as infrequent oil changes or the use of low-quality oil. I have found that regular oil changes, using the manufacturer-recommended oil type, can significantly extend the life of the PCV valve and the entire engine system. While some drivers may overlook this small component, its impact on overall engine health cannot be overstated.

It is also worth noting that the PCV system is interconnected with other components, such as the intake manifold and the fuel injection system. A malfunctioning PCV valve can introduce unmetered air into the intake, leading to an incorrect air-fuel mixture. This can cause a range of drivability issues, including poor acceleration, rough idle, and increased emissions. In my experience, this can often lead to unnecessary diagnostic trouble codes, complicating the troubleshooting process.

In vehicles equipped with turbochargers, the role of the PCV valve becomes even more critical. The increased pressures and temperatures in these systems can lead to rapid degradation of the PCV components. I have encountered instances where a failing PCV valve in a turbocharged engine resulted in excessive oil being forced into the intake system, leading to significant power loss and potential turbocharger damage.

In terms of maintenance, while the PCV valve is often overlooked, I have found that it is beneficial to include it in routine inspections. A simple visual check can reveal signs of wear or blockage. Many valves are designed to last the life of the vehicle, but environmental factors, driving conditions, and engine maintenance can all influence their longevity. In some vehicles, replacing the PCV valve is a straightforward task that can prevent more significant issues down the road.

The symptoms of a malfunctioning PCV valve can vary widely depending on the vehicle and engine design. Some drivers may experience a noticeable decrease in fuel efficiency, while others may not notice any immediate changes until more severe symptoms arise. It is important to pay attention to the engine's behavior and be proactive about maintenance.

When considering replacements, it is crucial to source quality parts. I have seen instances where aftermarket PCV valves fail prematurely, leading to the same issues the driver was attempting to resolve. Sticking with OEM parts can often be a wiser choice, ensuring that the component fits correctly and meets the specifications required for optimal performance.

In summary, the PCV valve may be a small part of the engine system, but its impact is significant. From oil consumption to engine pressure and emissions, this component plays a pivotal role in maintaining the health of the engine. Regular inspections and maintenance can prevent many issues associated with a failing PCV valve. Given the interconnected nature of modern engine systems, being vigilant about the PCV valve can help ensure a smoother, more efficient driving experience.