Disconnecting fuel line fittings is a task that many automotive technicians encounter regularly. While it may seem straightforward, various factors can complicate the process. In my years of experience working on different vehicles, I’ve encountered numerous situations that highlight the nuances of fuel line disconnection. Understanding these challenges can save time and prevent damage during maintenance or repair.

One of the first considerations is the type of fuel lines present in the vehicle. Different manufacturers have adopted various designs over the years. Some vehicles utilize quick-connect fittings, while others may employ threaded connections. The former can often be more user-friendly, allowing for a simple push and pull mechanism. However, over time and with exposure to heat and fuel, these fittings can become brittle or sticky, making disconnection more challenging than anticipated.

In my experience, the most common issue arises from a lack of maintenance. Fuel lines are typically made from materials designed to withstand harsh conditions, but they are not immune to wear. For instance, rubber hoses can degrade over time, especially if they are exposed to high temperatures or harsh chemicals. This degradation can cause the fittings to seize, making them difficult to disconnect. In some cases, attempting to force a connection apart can lead to the hose tearing, resulting in fuel leaks and potential fire hazards.

When preparing to disconnect a fuel line, it’s wise to consider the pressure within the fuel system. Fuel lines are pressurized, and a sudden release of pressure can lead to fuel spraying. This not only creates a safety hazard but can also lead to an unpleasant cleanup. I have found that relieving the fuel pressure before disconnecting the lines is an essential step that should not be overlooked. This can often be done by removing the fuel pump fuse and running the engine until it stalls, or by using a pressure relief valve if equipped.

Identifying the Right Tools

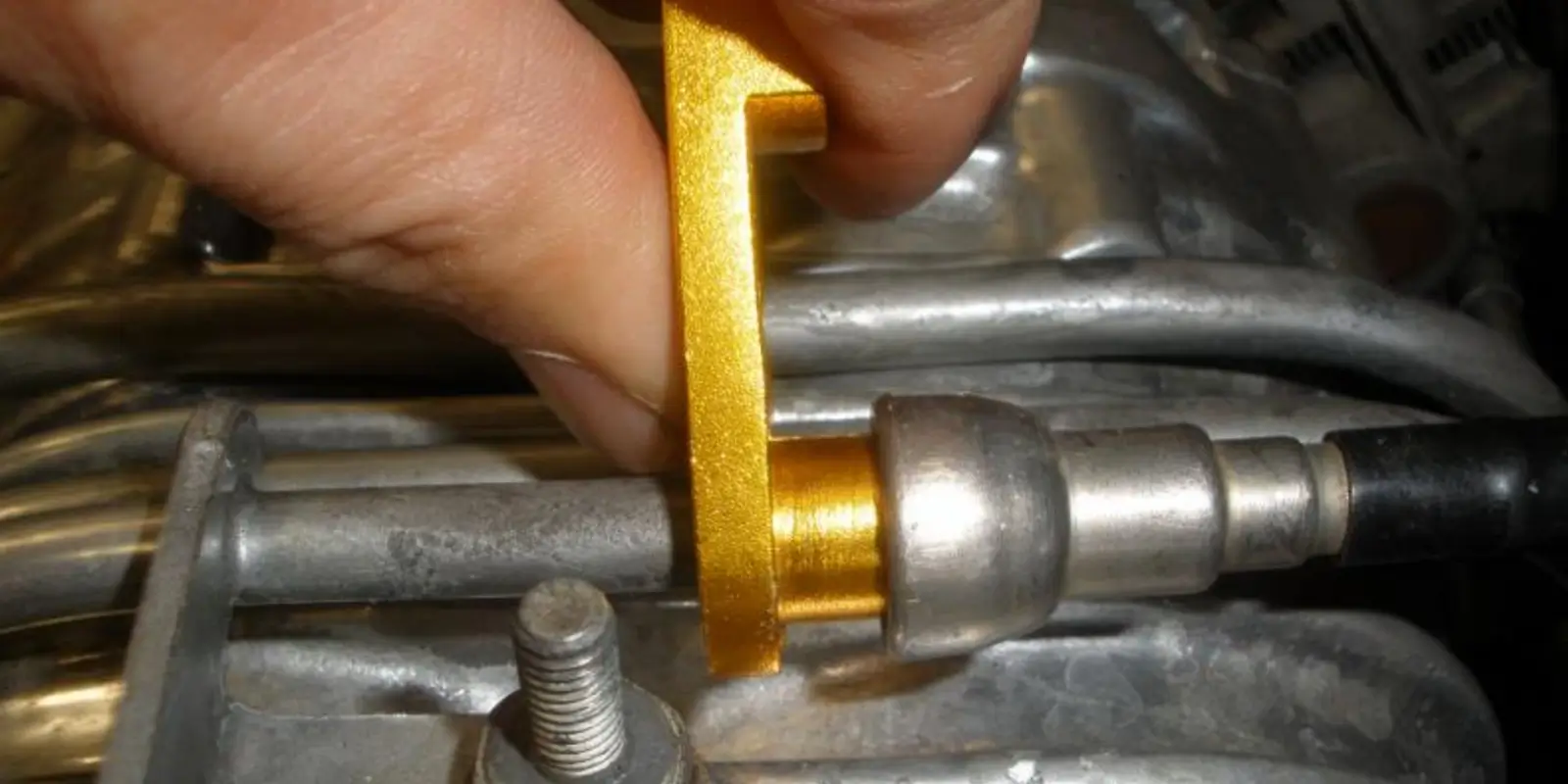

The tools required to disconnect fuel lines can also impact the ease of the job. Standard pliers may not be sufficient for certain types of quick-connect fittings. In many cases, a specialized fuel line disconnect tool is necessary. These tools are designed to fit specific fittings and can prevent damage to both the line and the fitting during disconnection. I have seen technicians attempt to improvise with common tools, only to end up damaging the fittings or the lines themselves, leading to more extensive repairs.

Another aspect to consider is the accessibility of the fuel lines. In many modern vehicles, the fuel lines are located in tight spaces that can be difficult to work in. This can be particularly true for vehicles with rear-mounted fuel tanks or those equipped with complex underbody layouts. Limited space can make it challenging to apply the necessary force to disconnect a fitting without risking injury or damaging surrounding components. It’s often beneficial to have a clear workspace and to use extensions or swivel sockets when dealing with hard-to-reach fittings.

Common Issues and Their Causes

One of the prevalent issues I’ve encountered is the corrosion of fittings, especially in older vehicles or those exposed to harsh environments. Corrosion can occur due to a combination of moisture and fuel exposure, leading to a bond that can be nearly impossible to break without damaging the components. In such cases, applying penetrating oil can help, but it’s essential to let it sit for a while to ensure it seeps into the threads or connections. Rushing this process can lead to frustration and potential damage.

In some instances, the fuel line may be connected to a component that is also corroded or damaged. For example, if the line connects to a fuel filter or fuel rail that has seen better days, attempting to disconnect the line could result in breaking the component. This scenario often leads to a more complicated repair process, as it may require replacing multiple parts rather than just the fuel line itself.

Environmental Considerations

Environmental factors can also play a significant role in the condition of fuel lines and their fittings. For instance, vehicles driven in colder climates may experience issues with fuel line freeze-up, particularly if there are any leaks or cracks in the line. Conversely, in hot climates, fuel lines exposed to high temperatures can become brittle and susceptible to breaking. These conditions can complicate the disconnection process and may necessitate additional precautions, such as warming the lines gently or using heat-resistant tools to prevent damage.

Moreover, the type of fuel being used can influence the longevity and integrity of fuel lines. Ethanol-blended fuels, for example, can cause certain rubber components to degrade faster than traditional gasoline. This degradation can lead to leaks or weak connections, making disconnection a more precarious task. I have seen instances where technicians have overlooked the type of fuel being used, leading to unexpected problems during routine maintenance.

Safety Precautions

Safety should always be a top priority when working with fuel systems. The risk of fire or explosion is significant, and it’s crucial to take appropriate measures before beginning work. Ensuring proper ventilation in the workspace is essential, as is keeping a fire extinguisher readily accessible. Wearing safety goggles and gloves can also protect against fuel splashes and harmful vapors.

In addition, it’s wise to keep a spill kit on hand. Even with the best precautions, spills can happen, and being prepared can mitigate risks. I’ve often found that having the right safety equipment and protocols in place can make a substantial difference in the overall experience of working with fuel lines.

Disconnecting fuel lines is a task that requires attention to detail and an understanding of the specific vehicle’s systems. Each vehicle presents its own set of challenges, influenced by factors such as age, environmental conditions, and fuel type. Recognizing these variables can lead to a smoother process and help avoid unnecessary complications. It’s a task that, while routine, can reveal deeper issues if not approached with caution and respect for the intricacies of automotive engineering.