The camshaft and crankshaft are two fundamental components in the internal combustion engine, each playing a critical role in the engine's overall operation. Despite their differences in function and location, they work in concert to facilitate the combustion process that powers vehicles. Over the years, I have encountered numerous scenarios where issues with these components have led to significant performance problems, and understanding their roles can help diagnose various engine-related challenges.

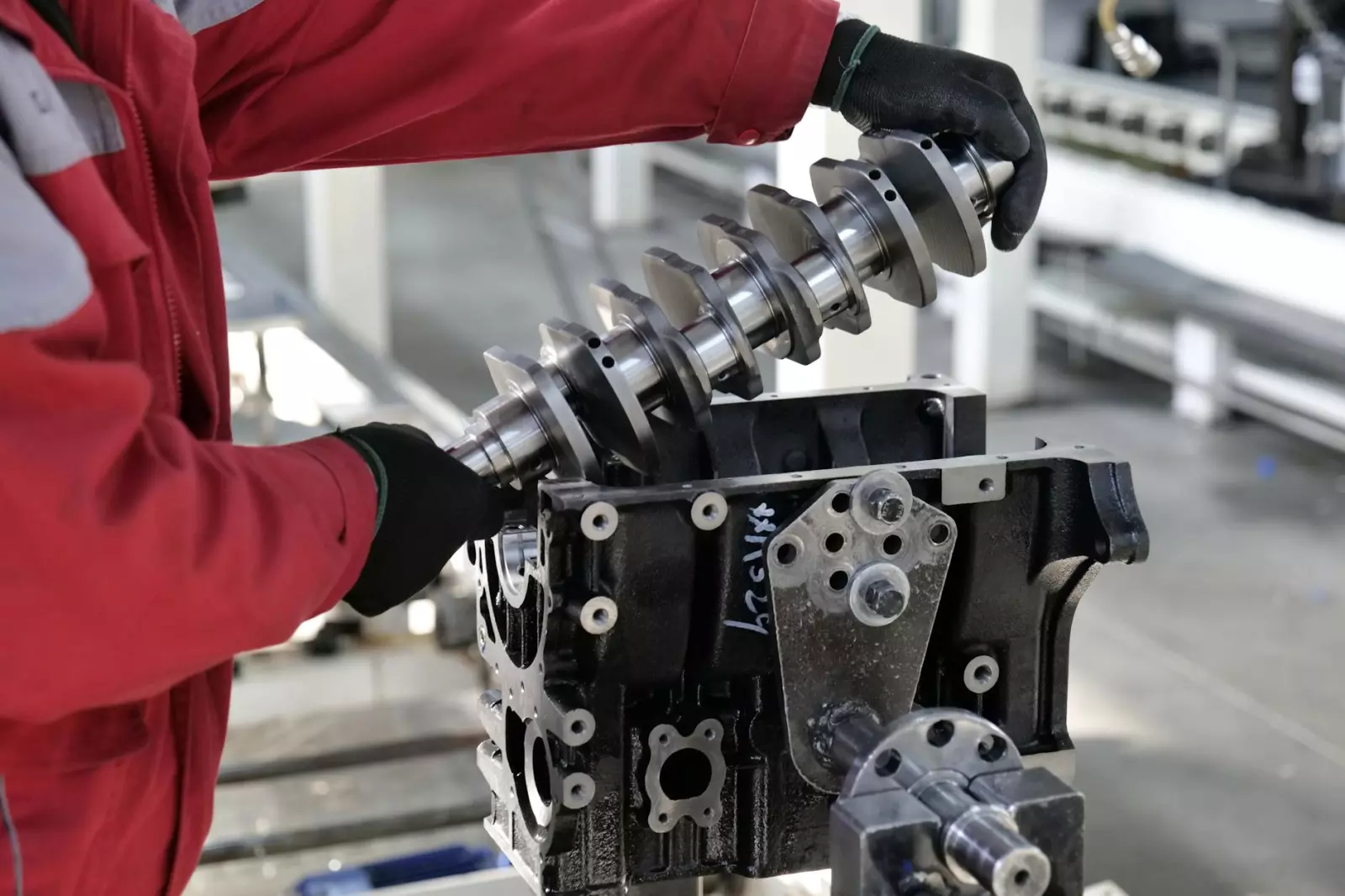

The crankshaft is primarily responsible for converting the linear motion of the pistons into rotational motion, enabling the vehicle's wheels to turn. It is typically located at the bottom end of the engine and is connected to the pistons via connecting rods. As the pistons move up and down during the combustion cycle, the crankshaft rotates, translating this linear movement into rotational energy. This transformation is critical for the operation of the vehicle, as it directly influences power delivery and efficiency.

In contrast, the camshaft operates at the top end of the engine and is tasked with controlling the timing of the intake and exhaust valves. It does this through a series of lobes that push against rocker arms or directly actuate the valves, allowing air and fuel into the combustion chamber while expelling exhaust gases. The camshaft's timing is crucial; if it is out of sync with the crankshaft, the engine can suffer from poor performance, misfires, or even catastrophic failure.

One common issue I have encountered with crankshafts is wear and tear on the main bearings. Given the high loads and stresses they endure, these bearings can become worn over time, leading to increased clearance and ultimately a loss of oil pressure. This situation is often exacerbated in engines that are subjected to high RPMs or heavy loads, resulting in knocking sounds and potential engine damage. Regular oil changes and using the correct viscosity oil can help mitigate some of these issues, but once significant wear occurs, replacement of the crankshaft may be necessary.

Similarly, camshafts can also experience failure, particularly in high-performance applications where stress levels are elevated. A common failure mode is the wear of the lobes, which can lead to a loss of valve lift and timing accuracy. This wear is often accelerated by insufficient lubrication or the use of low-quality oil. In my experience, engines that are frequently run at high RPMs without proper oil maintenance often exhibit these symptoms. Addressing camshaft wear early can prevent more extensive engine damage and costly repairs.

Another aspect to consider is the relationship between the camshaft and crankshaft, which is governed by a timing belt or chain. If this component fails, the synchronization between the two shafts is lost, leading to what is known as "valve float," where the valves may collide with the pistons. This scenario can result in severe engine damage and is often a costly repair. Regular inspection of timing belts and chains, along with adherence to manufacturer-recommended replacement intervals, can help prevent such failures.

The design of these components has evolved over the years, with advancements in materials and engineering techniques. For instance, modern engines may employ variable valve timing (VVT) systems that adjust the camshaft position to optimize performance across a range of speeds and loads. While these systems can enhance efficiency and power, they also introduce additional complexity that can lead to new failure modes. I have seen instances where the VVT actuator fails, causing erratic engine performance and triggering check engine lights.

In summary, both the camshaft and crankshaft are vital to the engine's operation, and their failures can lead to significant performance issues. Understanding their functions and the common problems associated with them can aid in early detection and maintenance. Regular inspections, appropriate lubrication, and timely replacement of worn components are essential practices for ensuring the longevity and performance of these critical engine parts. Recognizing the symptoms of wear or failure early on can mean the difference between a simple repair and a complete engine overhaul.