Fuel pressure is a critical aspect of any internal combustion engine’s operation. It influences fuel delivery, engine performance, and overall vehicle reliability. Over the years, I have encountered a range of fuel pressure-related issues across various vehicles, from passenger cars to commercial trucks. Each instance has reinforced the importance of understanding how fuel pressure operates and the potential problems that can arise when it is not within specified parameters.

Fuel pressure is generated by the fuel pump, which draws fuel from the tank and sends it through the fuel lines to the engine. This pressure must be maintained within a specific range to ensure optimal performance. When fuel pressure is too low, the engine may struggle to start or run smoothly. Conversely, excessively high fuel pressure can lead to fuel delivery problems, potentially causing engine damage. From my experience, fuel pressure issues often manifest in symptoms that can be misdiagnosed, leading to unnecessary repairs and costs.

Common symptoms of low fuel pressure include engine misfires, difficulty starting the vehicle, and poor acceleration. In many cases, the driver might notice a lack of power during acceleration, particularly when climbing hills or under heavy loads. These symptoms can be exacerbated by engine temperature, load conditions, and even the quality of the fuel being used. For instance, I have seen vehicles with low fuel pressure struggle more when the engine is hot, as the fuel pump may not be able to maintain adequate pressure due to thermal expansion or wear.

On the other hand, high fuel pressure can lead to a different set of problems. When the pressure exceeds manufacturer specifications, it can cause fuel to bypass the injectors or flood the combustion chamber, leading to poor fuel economy and increased emissions. I once worked on a truck that was experiencing rough idling and excessive fuel consumption due to a failing pressure regulator. The symptoms were subtle at first, but over time, they became more pronounced, illustrating how critical it is to monitor fuel pressure regularly.

Understanding Fuel Pressure Regulation

Fuel pressure regulation is primarily managed by the fuel pressure regulator, which maintains the pressure within the fuel rail. This component can fail for various reasons, including wear and tear, contamination, or a failure in the vacuum line that controls it. In vehicles equipped with returnless fuel systems, the regulator is often integrated into the fuel pump assembly, making it more challenging to diagnose. I have encountered several instances where a simple inspection of the regulator’s vacuum line revealed cracks or disconnections that were contributing to erratic fuel pressure readings.

In many cases, the fuel filter can also play a significant role in fuel pressure issues. A clogged fuel filter can restrict fuel flow, leading to low pressure. I’ve seen vehicles with restricted filters that exhibited symptoms of low fuel pressure, only to find that replacement of the filter resolved the issue. Regular maintenance schedules often recommend changing the fuel filter, but it’s a task that can easily be overlooked, especially in older vehicles or those with less frequent service histories.

Diagnosing Fuel Pressure

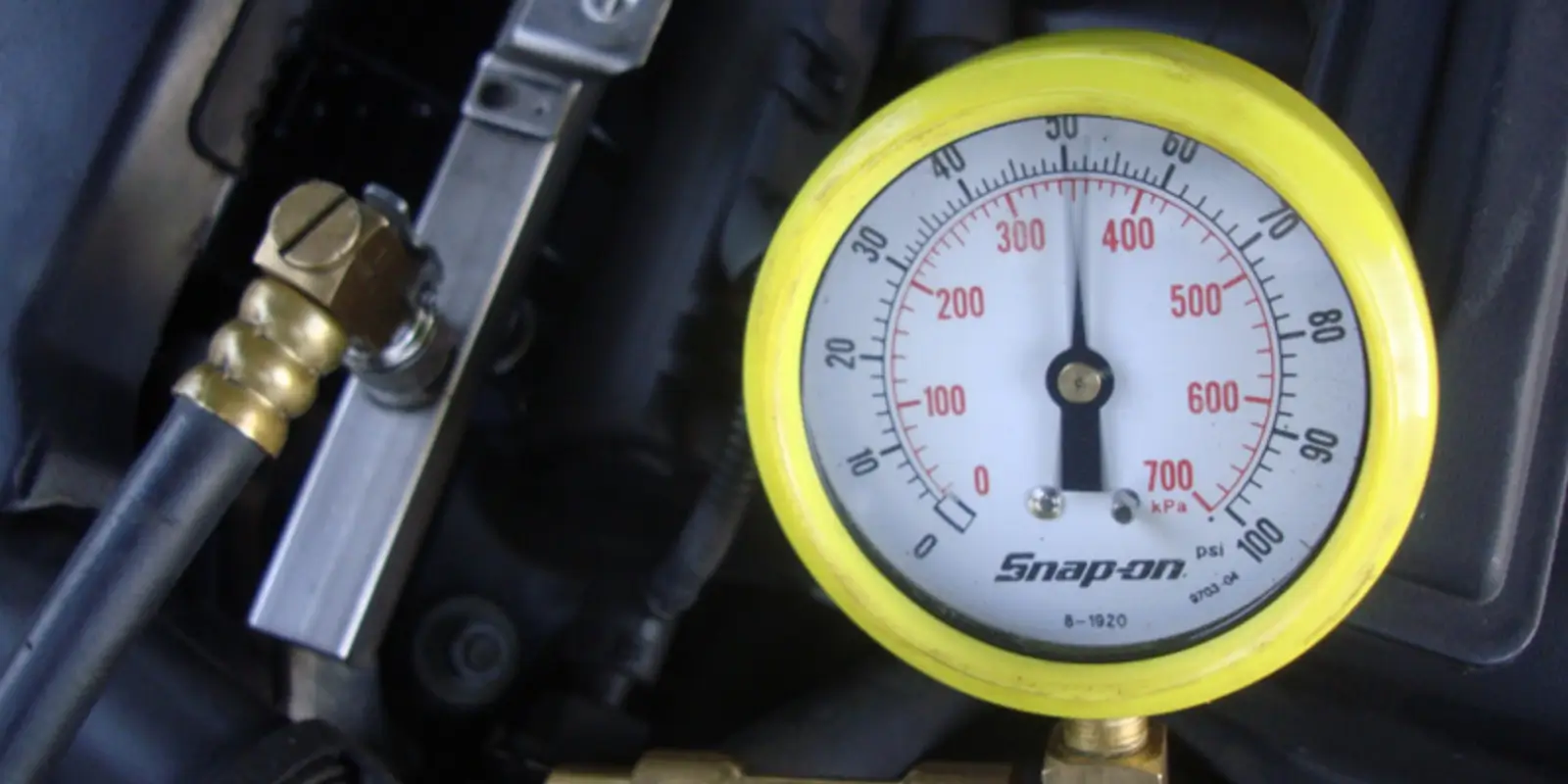

When diagnosing fuel pressure issues, a fuel pressure gauge is an essential tool. It allows for direct measurement of the fuel pressure at the fuel rail. I typically begin by connecting the gauge to the fuel rail test port, if equipped. Observing the pressure while cranking the engine gives a clear indication of whether the fuel system is functioning as intended. A reading below the manufacturer’s specified range often points to a failing pump, a clogged filter, or a faulty regulator.

Interestingly, I have found that intermittent fuel pressure issues can be particularly tricky to diagnose. These can arise due to electrical problems, such as a faulty relay or wiring issues affecting the fuel pump operation. In one case, I encountered a vehicle that would intermittently stall during operation. The fuel pressure gauge showed normal readings at idle, but a voltage drop during acceleration caused the pump to lose power, leading to a drop in pressure. This scenario highlights the importance of not only measuring fuel pressure but also understanding the electrical components that support the system.

Environmental Factors Affecting Fuel Pressure

Environmental conditions can significantly impact fuel pressure. High ambient temperatures can cause fuel to vaporize within the lines, leading to vapor lock, especially in older vehicles without modern fuel system designs. This situation becomes more pronounced in hot climates or during prolonged idling. Conversely, extremely cold temperatures can thicken fuel or cause condensation in the tank, leading to fuel line freeze-ups or other delivery issues. I have seen vehicles struggle to start during cold snaps, only to find that the fuel lines were partially frozen, obstructing flow.

Additionally, the quality of fuel can have a direct impact on fuel pressure. Contaminated fuel can lead to clogged injectors and filters, altering the pressure dynamics within the system. I’ve often advised vehicle owners to be cautious about where they refuel, particularly in areas where fuel quality is known to fluctuate. Poor fuel quality can lead to long-term damage that manifests as fuel pressure inconsistencies.

Long-term Considerations

Over time, fuel system components can wear down and require replacement. Fuel pumps, in particular, have a finite lifespan, often dictated by mileage and usage patterns. I have encountered many vehicles where the original fuel pump was still operational but was struggling to maintain pressure due to age and wear. It’s not uncommon for pumps to begin to fail gradually, leading to performance issues that can be mistaken for other engine problems. Regular inspections and understanding the signs of impending failure can help mitigate some of these issues.

While diagnosing fuel pressure problems, it is essential to consider the entire fuel system holistically. This approach includes inspecting fuel lines for leaks, checking electrical connections, and ensuring all components are functioning as intended. I have seen instances where a simple visual inspection revealed cracked lines or corroded connectors, which were the root cause of fluctuating fuel pressure readings.

Fuel pressure issues can often signal a more extensive problem within the fuel system or engine management. Addressing these symptoms promptly is critical to prevent further damage and maintain vehicle reliability. Regular monitoring and a methodical approach to diagnostics can lead to better outcomes, ensuring that vehicles remain safe and efficient on the road.