Fuel injectors are crucial components in modern fuel delivery systems, playing a pivotal role in the performance and efficiency of internal combustion engines. Over time, these components can fail due to various factors, leading to symptoms that may not always indicate the need for immediate replacement. Having worked extensively on a variety of passenger cars, pickup trucks, and commercial vehicles, I have encountered numerous scenarios where the replacement of fuel injectors became necessary. Each case often reveals deeper issues worth considering.

Fuel injectors operate under high pressure and are responsible for precisely delivering fuel into the combustion chamber. They work in conjunction with the engine control unit (ECU), which determines the timing and amount of fuel needed based on various inputs such as engine speed, load, and temperature. Failures can manifest in several ways: reduced fuel efficiency, rough idling, misfires, and even increased emissions. In my experience, these symptoms can sometimes be misleading, as they might stem from other issues, such as a malfunctioning ECU, clogged fuel filters, or even problems with the fuel pump.

One of the most common signs of a failing fuel injector is poor engine performance. Drivers often report a noticeable decrease in acceleration or power, particularly under load or during highway driving. This can be misattributed to other components like the air intake system or exhaust, but it’s essential to consider the injectors as a potential culprit. In some cases, the issue may be as simple as a dirty injector that can be cleaned rather than replaced. However, if the injector is physically damaged or has developed a leak, a replacement is necessary.

Heat is a significant factor in the longevity of fuel injectors. In many vehicles, the engine compartment can reach extreme temperatures, which can accelerate wear on the injector seals and internal components. For instance, I’ve seen injectors fail in hot climates where the ambient temperature exacerbates the heat generated by the engine. This often leads to leakage or a decrease in injector spray pattern, which affects fuel atomization and combustion efficiency. Regular maintenance can mitigate some of these issues, but in high-mileage vehicles, injector replacement becomes a common task.

Another common oversight in diagnosing fuel injector problems is the fuel supply system. A failing fuel pump or a clogged fuel filter can cause low fuel pressure, leading to injector performance issues. In some instances, replacing the injector without addressing the root cause can result in premature failure of the new component. Therefore, it’s prudent to assess the entire fuel system when diagnosing injector-related issues. This includes checking for proper fuel pressure and flow rates, which can often be done with a fuel pressure gauge.

In addition to performance issues, fuel injectors can also impact emissions. A malfunctioning injector can lead to incomplete combustion, resulting in higher levels of unburnt fuel in the exhaust. This is particularly concerning in vehicles subject to emissions testing, as it can result in failed tests and costly repairs. Observing the vehicle’s emissions output can provide clues about injector performance. In my experience, it is not uncommon for technicians to overlook the injectors during diagnostics, focusing instead on the exhaust system or catalytic converters.

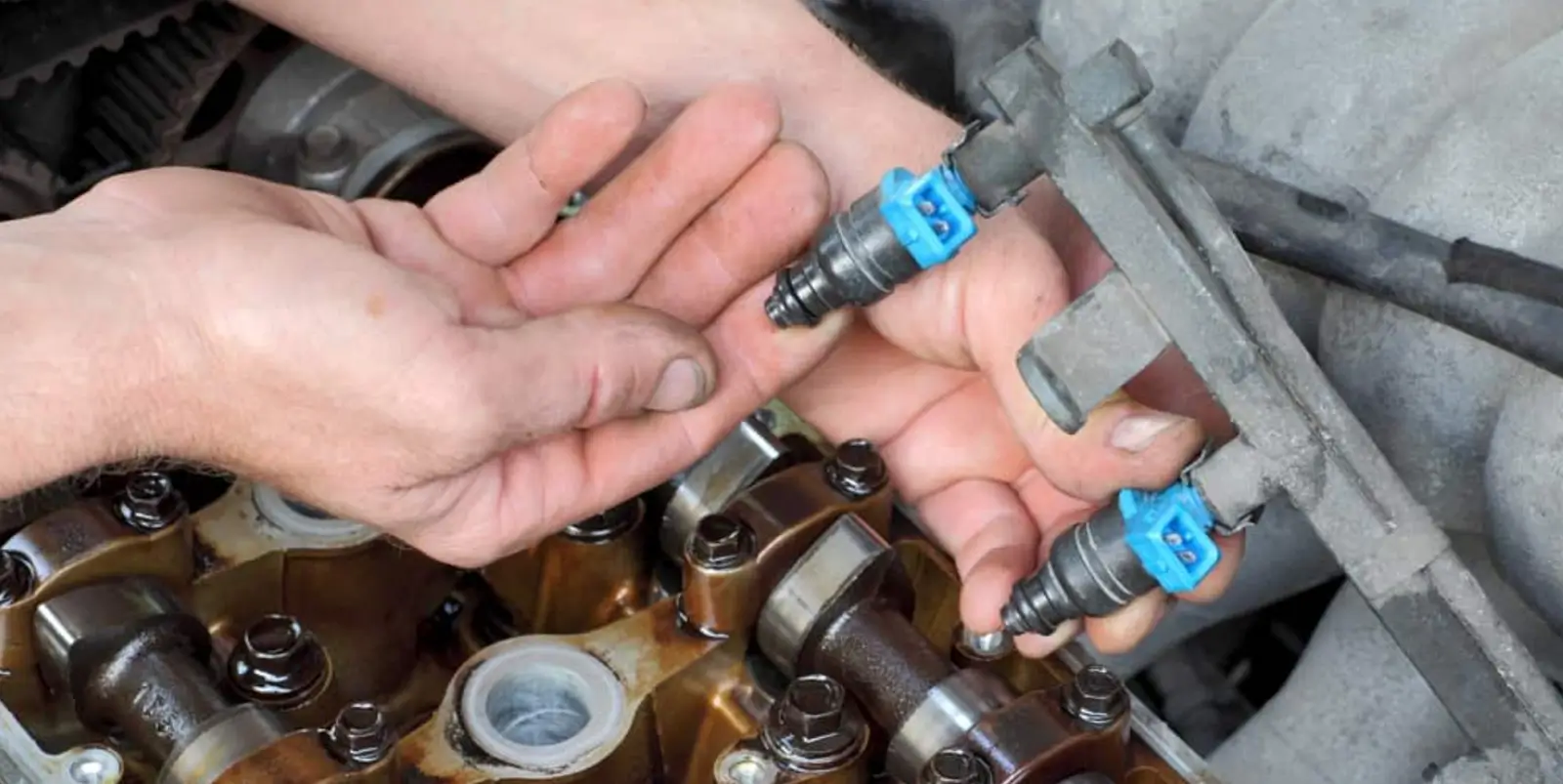

When it comes to replacing fuel injectors, the installation process can sometimes present challenges. Many vehicles have injectors that are difficult to access, requiring the removal of other components such as the intake manifold or even the engine itself in some cases. This adds to the complexity and time required for the job. Care must be taken to ensure that all connections are secure and that the injectors are seated properly to avoid leaks. I’ve encountered situations where a seemingly minor oversight during installation led to fuel leaks, necessitating a return to the shop for further adjustments.

Additionally, the compatibility of replacement injectors is crucial. While it may be tempting to use aftermarket injectors, it’s essential to choose components that meet the specifications of the original equipment. Mismatched injectors can lead to poor performance, increased emissions, and potential damage to the engine. In my experience, using OEM parts often leads to better long-term reliability, especially in vehicles with complex fuel management systems.

The longevity of fuel injectors can also be influenced by driving habits and fuel quality. Vehicles that frequently undergo short trips may experience more injector buildup due to incomplete combustion and fuel residues. Similarly, using low-quality fuels can result in deposits forming on the injectors, leading to reduced efficiency and performance. In areas with poor fuel quality, I have seen injectors fail far earlier than expected, necessitating more frequent replacements.

Another aspect to consider is the age of the vehicle. Older vehicles may have injectors that have simply reached the end of their service life. While many modern injectors are designed to last longer and withstand harsher conditions, age-related wear can’t be overlooked. In my experience, vehicles with over 100,000 miles often require more attention to the fuel system, including the injectors. Regular inspection during routine maintenance can help catch issues before they lead to significant performance problems.

In certain scenarios, the symptoms of a failing injector can be mistaken for other issues, such as ignition problems or even issues with the transmission. A misfire, for example, could be attributed to a faulty spark plug or ignition coil rather than a fuel delivery issue. This highlights the importance of a thorough diagnostic approach, considering all potential causes rather than jumping directly to conclusions.

Moreover, environmental factors can play a role in the degradation of fuel injectors. Vehicles operating in extremely cold weather may experience issues with fuel flow, while those in humid environments can face challenges with corrosion. Understanding the conditions in which a vehicle operates can provide insights into potential injector failures.

Fuel injectors are vital components that require careful attention during diagnosis and replacement. Their failure can significantly affect engine performance, fuel efficiency, and emissions. The complexity of modern fuel systems necessitates a holistic approach when dealing with injector issues. Observing the broader context of the vehicle’s performance, maintenance history, and environmental factors can aid in making informed decisions regarding repairs and replacements. Recognizing that symptoms can be misleading is crucial in diagnosing and addressing fuel injector problems effectively.