The exhaust system in a vehicle is a critical component that serves multiple functions. It not only directs harmful gases away from the engine and cabin but also plays a vital role in the overall performance and efficiency of the vehicle. Over the years, I have encountered various scenarios that highlight the importance of understanding how exhaust pipe temperatures can affect both the vehicle’s operation and its longevity.

Exhaust pipes can reach remarkably high temperatures during operation, often exceeding 1,000 degrees Fahrenheit. These temperatures can vary based on several factors, including engine load, speed, and the specific design of the exhaust system. For example, during heavy acceleration or when towing a load, exhaust temperatures can spike significantly. This is a normal occurrence, yet it can lead to several issues if not monitored or addressed appropriately.

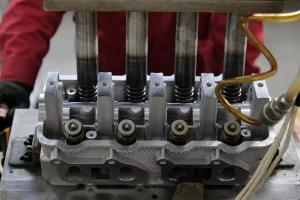

One common observation is that the materials used in the exhaust system, typically stainless steel or aluminized steel, have different tolerances to heat. Stainless steel is more resistant to rust and corrosion, but even it can become brittle over time if subjected to extreme temperatures consistently. Aluminized steel, while lighter and less expensive, is more prone to degradation in high-heat environments. This degradation can manifest as cracks or holes in the exhaust pipes, often leading to exhaust leaks that compromise engine performance and efficiency.

In my experience, one of the first signs of trouble in the exhaust system is often a change in sound. A noticeable increase in noise can indicate an issue, particularly if it comes with a distinct rumble or hissing sound. These symptoms might suggest a leak somewhere along the exhaust path, potentially at the joints or where the pipe connects to the muffler. The leak not only allows exhaust gases to escape but can also lead to increased back pressure in the system, affecting engine performance.

Heat also has a secondary effect on surrounding components. For instance, in vehicles with turbocharged engines, the proximity of the exhaust system to other critical components, such as the intercooler or fuel lines, can lead to heat soak, where nearby components become excessively hot. This can affect the performance of the intercooler, leading to decreased efficiency and increased intake temperatures. In some cases, I have seen fuel lines damaged due to excessive heat from nearby exhaust pipes, resulting in leaks that can pose serious safety hazards.

In addition to leaks and heat soak, prolonged exposure to high temperatures can lead to the degradation of exhaust gaskets. These gaskets are essential for maintaining a tight seal between exhaust components and preventing leaks. Over time, they can harden and crack due to thermal cycling, which can lead to exhaust gases escaping and creating further performance issues. Replacing these gaskets when they show signs of wear is a relatively straightforward maintenance task, yet it is often overlooked until more severe problems arise.

Another aspect to consider is the impact of exhaust temperatures on catalytic converters. These components are designed to operate efficiently at high temperatures, but they can be damaged if the temperatures exceed their operational limits for extended periods. A failing catalytic converter can lead to increased emissions and may trigger a check engine light. In some cases, I have encountered vehicles where the catalytic converter was replaced, only to discover that the underlying issue was excessive exhaust temperatures caused by a malfunctioning thermostat or a restricted exhaust flow.

The introduction of aftermarket exhaust systems can also influence temperature dynamics. Many vehicle enthusiasts opt for performance exhaust systems that improve flow and reduce back pressure. While these systems can enhance performance, they can also alter the temperature profile of the exhaust system. In some instances, I have seen vehicles with aftermarket exhausts experience higher temperatures than stock systems due to reduced heat shielding or less effective thermal management. This can lead to premature component failure if not properly addressed.

In addition to the physical components of the exhaust system, the vehicle’s onboard diagnostics can provide valuable insights into exhaust temperatures. Modern vehicles are equipped with various sensors that monitor exhaust conditions, including oxygen sensors and temperature probes. These sensors can help identify problems early, allowing for timely repairs. However, it’s essential to remember that sensor readings can be influenced by numerous factors, including engine tuning and the quality of the fuel used. In my experience, ensuring that the vehicle is running on the correct fuel type and maintaining a clean air filter can help optimize exhaust temperatures and overall engine performance.

It’s also worth noting that extreme environmental conditions can exacerbate issues related to exhaust temperatures. For instance, operating a vehicle in extremely cold climates can lead to condensation forming in the exhaust system, which can mix with soot and create corrosive byproducts. Conversely, in hot climates, the heat can amplify the risk of component failure. Regular inspections of the exhaust system, especially in vehicles subjected to harsh conditions, can help mitigate these risks.

In summary, the temperatures that exhaust pipes reach during vehicle operation are significant and can lead to various issues if not managed properly. From leaks and heat soak to the degradation of surrounding components, understanding the dynamics at play is crucial for maintaining vehicle performance. Regular maintenance and monitoring can prevent minor issues from escalating into more severe problems, ensuring the longevity and efficiency of the exhaust system. Observing these factors in real-world scenarios can provide valuable insights into the intricate relationship between heat and vehicle performance.