The P0008 trouble code indicates a discrepancy in the engine position timing, specifically within the engine positioning system on Bank 1. This condition arises when the Engine Control Module (ECM) detects that the actual position of the camshaft does not align with the expected position based on the crankshaft’s position. The implications of this can range from minor performance issues to significant engine damage if left unaddressed.

A common scenario involves vehicles equipped with variable valve timing (VVT) systems, which rely on precise coordination between the camshaft and crankshaft. When the timing is off, it can lead to a range of symptoms, including poor acceleration, rough idling, and increased fuel consumption. In my experience, these symptoms often emerge under specific operational conditions – such as high load situations or elevated temperatures – where the engine is under stress.

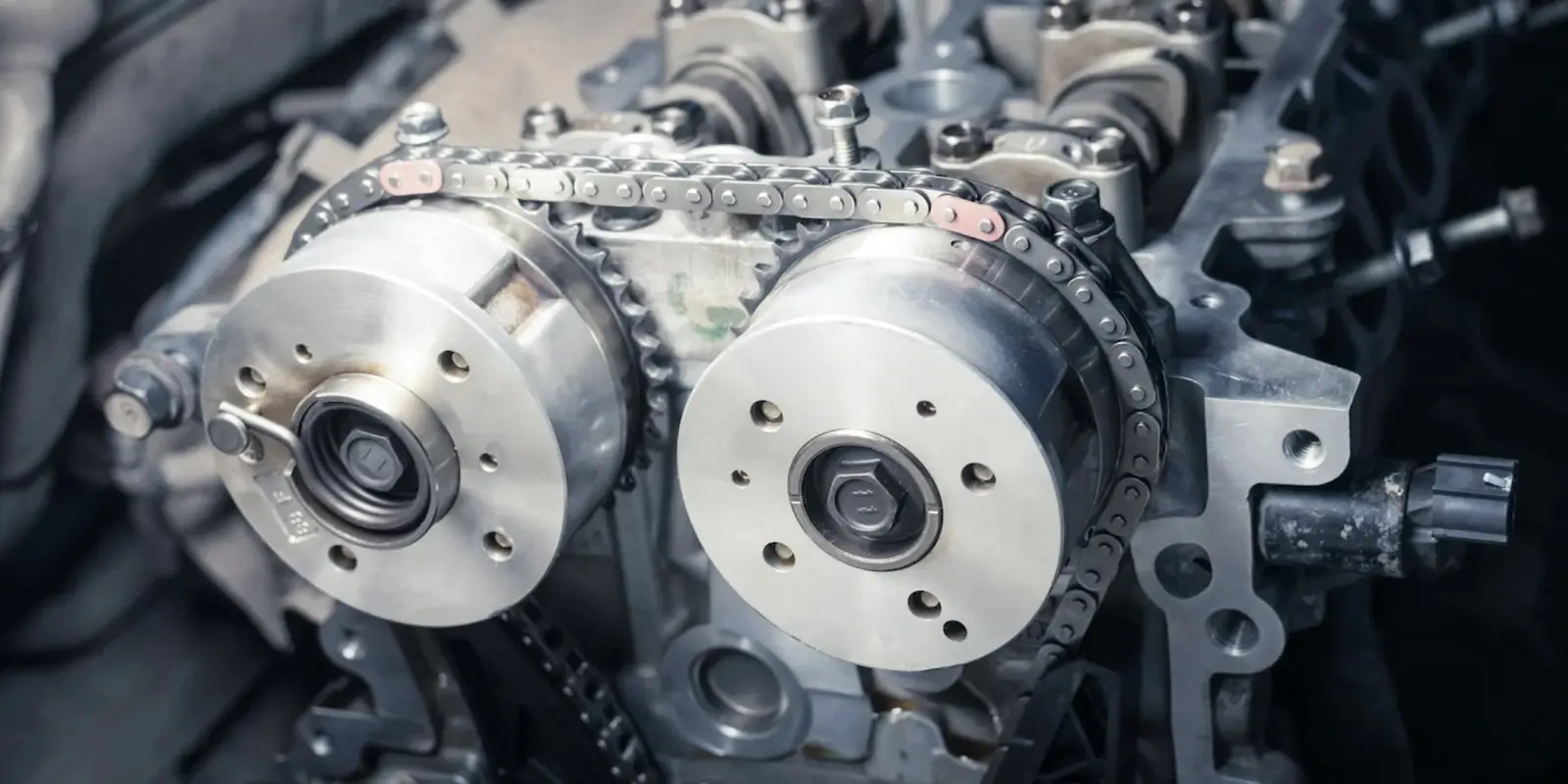

Real-world observations suggest that one of the primary causes of a P0008 code is a malfunctioning timing chain or belt. Over time, these components can stretch or wear, leading to misalignment. The timing chain’s tensioner, designed to maintain the correct tension on the chain, can also fail. This failure often goes unnoticed until the symptoms become pronounced. In some cases, the timing chain guides can wear down, causing the chain to slip.

Another area worth examining is the VVT solenoid. This component controls the flow of oil to the VVT system and is critical for the proper functioning of the engine’s timing mechanisms. If the solenoid becomes clogged or fails, it can lead to improper oil flow and, subsequently, inaccurate timing. I’ve encountered numerous instances where a simple solenoid replacement resolved the P0008 code, often overlooked in the diagnostic process.

Additionally, a faulty camshaft or crankshaft position sensor can contribute to this issue. These sensors are responsible for relaying the position of the camshaft and crankshaft to the ECM. If they send inaccurate readings, the ECM may miscalculate the timing, triggering the P0008 code. In vehicles where these sensors have been replaced, I’ve observed a marked improvement in engine performance, often eliminating the code entirely.

It is essential to consider the condition of the engine oil as well. Sludge buildup or low oil levels can affect the hydraulic actuators used in VVT systems. Insufficient lubrication can lead to failure in timing adjustments, resulting in performance degradation. Regular oil changes and using the recommended oil type can mitigate some of these issues. In my experience, vehicles that have been well-maintained in this regard tend to experience fewer timing-related problems.

Temperature fluctuations can also play a significant role in the appearance of the P0008 code. High temperatures can cause components to expand and contract, potentially exacerbating wear and leading to misalignment. In regions with extreme climates, I’ve seen vehicles that are more prone to these issues, particularly if they have not been serviced regularly.

When diagnosing P0008, it is also crucial to consider the possibility of a wiring issue. The connectors and wiring associated with the timing components can become damaged or corroded over time. A thorough inspection of the wiring harness can reveal broken connections or shorts, which may not be immediately apparent during a standard diagnostic check. In some cases, simply repairing or replacing damaged wiring has resolved the P0008 code.

While some symptoms associated with a P0008 code may appear harmless, they can indicate deeper problems that could lead to significant engine damage if not addressed. For instance, prolonged engine misalignment can result in valve contact with the pistons, leading to catastrophic engine failure. This is particularly true in interference engines, where even a slight timing discrepancy can have dire consequences.

In some vehicles, I’ve noted that the P0008 code can be accompanied by other trouble codes, such as P0016 or P0017, which pertain to camshaft and crankshaft correlation. These codes can provide additional context for the underlying issue and help narrow down the diagnostic process. It’s not uncommon to find that multiple components are contributing to the problem, and addressing only one may not resolve the issue entirely.

In summary, the P0008 code is a multifaceted issue that can stem from various mechanical failures, sensor malfunctions, or wiring problems. Each vehicle presents unique challenges based on its design, maintenance history, and operating conditions. The key to effective diagnosis lies in a comprehensive assessment of the engine’s timing system and associated components.

Given the potential for severe engine damage, it is prudent to address a P0008 code promptly. While some symptoms may seem minor, the cascading effects of neglecting timing issues can lead to costly repairs and prolonged downtime. In my experience, a detailed approach to diagnosing and addressing the root cause of the P0008 code not only resolves the immediate issue but also enhances overall engine performance and longevity.